2. Drive screw

Auxiliary Materials Required

■

Lubricant for the drive screw: Isoflex Topas 30

■

Lubricant for the guides: Klüberquiet BQ 72

‑

72

Relubricating

Under laboratory conditions, it is only necessary to relubricate the L-505.023212 in

exceptional cases. For continuous industrial use, the lubrication intervals must be defined

individually.

If you have any questions on relubricating, contact our

customer service department (p. 31)

.

8.3

Cleaning

Requirements

✓

You have disconnected the L-505.023212 from the electronics.

Auxiliary Materials Required

■

Soft, lint-free cloth

■

Mild cleaning agent or disinfectant

If you have any questions on the auxiliary materials recommended for the L-505.023212,

contact our

customer service department (p. 31)

NOTICE

Damage due to unsuitable cleaning agents!

Some cleaning agents can cause rusting on the L-505.023212 or dissolve plastics, paints or

adhesives.

►

Do not clean with water or acetone.

Cleaning the L-505.023212

1. Dampen the cloth with the cleaning agent or disinfectant.

2. Carefully wipe the surfaces of the L-505.023212.

8.4

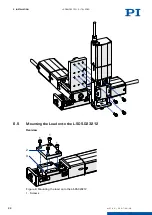

Moving the Motion Platform by Hand

It may be necessary to move the motion platform manually,

■

to allow access to the mounting holes in the positioner's base body for the mounting

screws,

■

to move the motion platform away from the mechanical hard stop and make the

L-505.023212 operational again.

Requirements

✓

You have disconnected the L-505.023212 from the electronics.

Moving the Motion Platform by Hand

1. Remove the protective earth connector. See

Connecting the L-505.023212 to the Protective

.

8 MAINTENANCE

L505M0017EN

‒

3/18/2020

27

M O T I O N | P O S I T I O N I N G