Page 22 of 30

b.

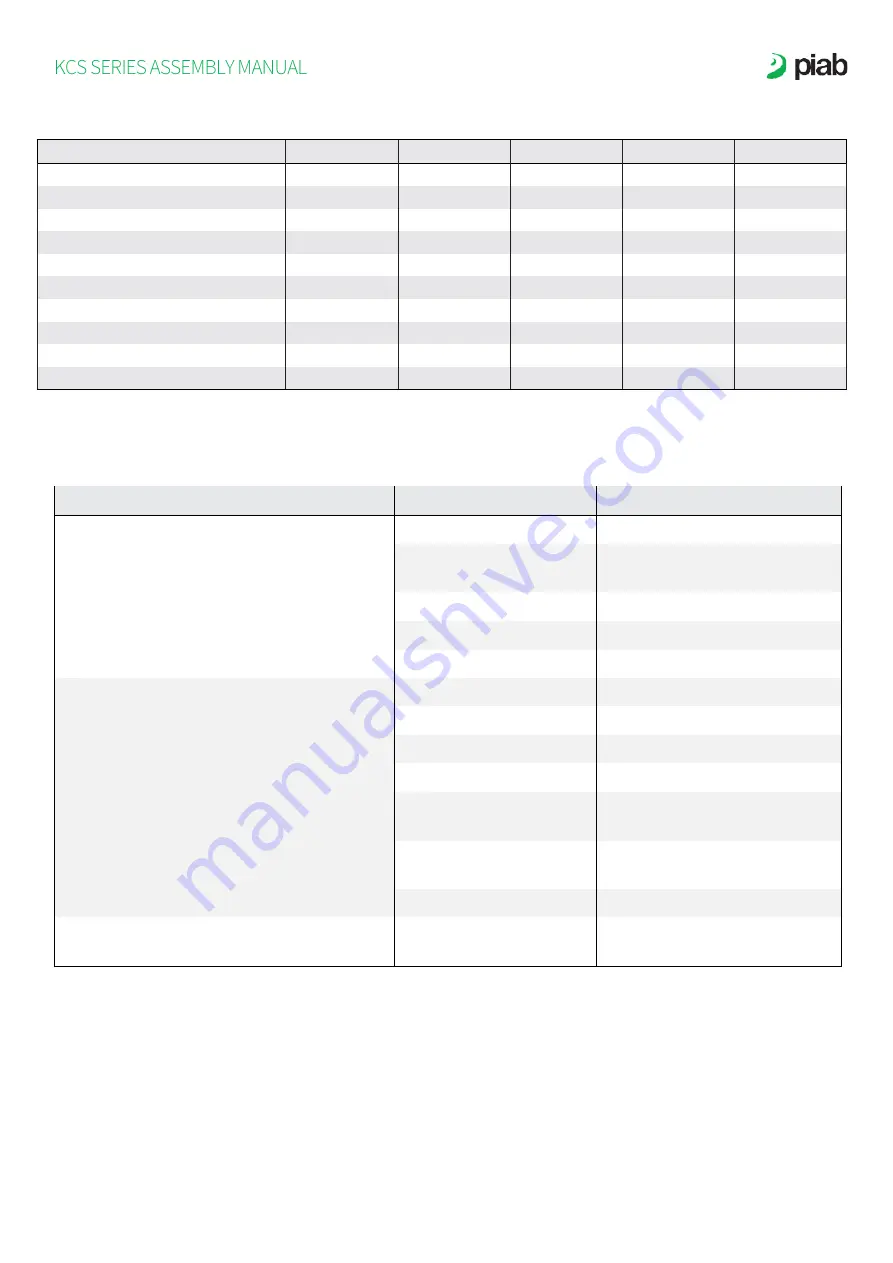

Maintenance plan

Daily

Weekly

Monthly

Every 6 months Every 12 months

Check Max vacuum level of the ejector

•

Check the micro holes

•

Check the silencer

•

Check tightening’s

•

Check the foam

•

Check supply air pressure

•

Check the electrical connection

•

Check the air connection

•

Check the general condition

•

Clean gripper exterior

•

9.

PROBLEMS/SOLUTIONS

Problem

Possible cause

Solution

Insufficient vacuum level or vacuum achieved too slowly

Operating pressure too low

Increase the pressure

Internal diameter of pressure hose

too small

Use hoses with larger internal diameter

Damaged sealing

Check and replace if necessary

Leak in pressure hose

Check hoses

Dirty ejector

Clean

Object not gripped

Low vacuum level

See above

Insufficient suction capacity

change the ejector version

Dirty micro holes

Clean

Lift is too fast

Slow down lift, avoid acceleration peaks

Pieces not suitable for lift with this

system

Replace grip solution

Occluded foam filter (with filter

version)

Clean

Occluded silencer

Replace silencer

Foam wears very quickly

The system is not corrected

placed on the workpiece

The gripping system must be parallel to

the workpiece surface

Note: We recommend always running preliminary tests with original samples. We are available for running such tests.