4

4 - 5

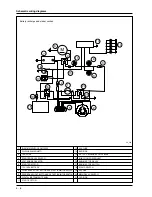

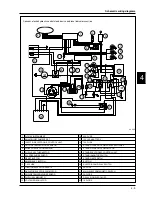

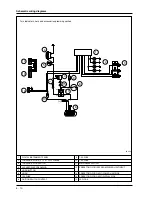

Electrical equipment diagram

Electrical equipment devices

1

. Digital instrument panel (11 LED indicators).

2

. Analog instrument panel (5 bulbs).

3

. Headlight (2 parking light bulbs, 55/55W low/high

beam bulbs).

4

. LH front turn indicators (10W bulb).

5

. Rear brake light button.

6

. Lights selector switch with headlight flash.

7

. Turn indicator switch.

8

. Horn button.

9

. Hazard warning light button.

10

. Reset button.

11

. Trumpet horn.

12

. Sidestand switch.

13

. Voltage regulator.

14

. Stand control unit.

15

. Engine stop relay switch.

16

. Electronic control unit relay switch.

17

. Stand pump relay switches.

18

. LH rear light (5W parking light bulb, 10W turn

indicator bulb).

19

. Rear brake light (5 x 2.3W bulbs).

20

. Number-plate light with bulb.

21

. RH rear light (5W parking light bulb, 10W turn

indicator bulb).

22

. 12V-14Ah battery.

23

. Fuse box (3 x 7.5A fuse, 1 x 15A fuse).

24

. Starting relay switch.

25

. Flywheel magneto (375W).

26

. Engine oil pressure sensor.

27

. Coolant temperature sensor.

28

. Engine rpm sensor.

29

. Air temperature sensor.

30

. Idle speed adjusting motor.

31

. Throttle potentiometer.

32

. Petrol injector.

33

. 2 stand switches.

34

. Stand pump motor.

35

. Injection electronic control unit.

36

. Decoder.

37

. Front brake light button.

38

. Engine stop switch.

39

. Wheel revolution sensor.

40

. RH front turn indicator (10W bulb).

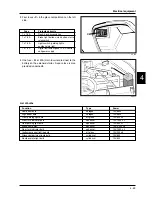

- When working on the electrical equip-

ment, take special care to ensure that the leads that link

up to the electronic control device are properly con-

nected by observing the polarity and colour coding of

the connectors.

ELECTRICAL CABLES COLOUR:

B

=White -

Bl

=Blue

-

G

=Yellow -

Mr

=Brown -

N

=Black -

BV

=White-Green -

GN

=Yellow-Black -

Gr

=Grey -

Rs

=Pink -

R

=Red -

Vi

=Violet -

V

=Green -

VN

=Green-Black -

BN

=White-

Black -

BBl

=White-Blue -

GV

=Yellow-Green -

Ar

=Orange -

Az

=Azure -

GrBl

=Grey-Blue -

GrN

=Grey-

Black.

Warning

41

. Relay switch.

42

. Lights switch.

43

. Start button.

44

. Stand button.

45

. Immobilizer aerial.

46

. Ignition switch.

47

. Electric fan.

48

. Electric fan relay switch.

49

. Main relay switch.

50

. HV coil.

51

. Fuel gauge with pump.

52

. Starter motor.

53

. Helmet compartment lamp button.

54

. Helmet compartment lamp.

55

. 12V socket.

56

. 2 rear fuse boxes for control unit (1 x 3A fuse, 1 x 5A

fuse, 1 x 10A fuse, 1 x 3A fuse).

57

. Radio display.

58

. Relay switch.

59

. Outside temperature sensor.

60

. Diode box (2 x 6A/2A diodes).

61

. Fuse box (2 x 7.5A fuse, 1 x 15A fuse, 1 x 5A fuse).

62

. Fuse box with base for stand pump (1 x 70A fuse).

63.

Intercom/radio control unit.

64.

Intercom connectors.

65.

Relay signaler glued.

Summary of Contents for X9 500 cc

Page 7: ...TABLE OF CONTENTS SPECIFIC TOOLING 2...

Page 17: ...TABLE OF CONTENTS ELECTRICAL EQUIPMENT 4...

Page 34: ...TABLE OF CONTENTS ENGINE 5...

Page 43: ...TABLE OF CONTENTS BRAKING SYSTEM 7...

Page 51: ...TABLE OF CONTENTS BODYWORK 8...