OPERATING AND INSTALLATION INSTRUCTIONS LG 250 A

PAGE 42

Changes reserved

U

S

ER

G

ENER

A

L

S

P

EC

IA

LIS

T

P

ER

S

O

NNEL

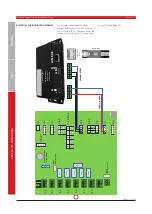

The unit's connectors must be connected

to air duct connections. Airtightness and

vibration isolation must be ensured.

Air pipes and attachments such as sound

absorbers etc. may only be attached to

the ventilation unit using adequately

dimensioned elements for mounting to

suitable solid wall or ceiling structural

components.

Avoid using flexible hoses for connections

to the unit. When making connections,

ensure in particular that no tools or

assembly material will fall into the

connections to the unit or onto the

unit itself. This could cause damage

components such as fan blades. Air

duct and installation components must

be suitably and adequately insulated in

accordance with project specifications.

CONNECTING AIR DUCTS AND COMPO-

NENTS

1. Supply air connection ø160 mm

2. Extract air connection ø160 mm

3. Outdoor air connection ø160

4. Exhaust air connection ø160

5. Cable inlets 4 x M16 / 1 x M12

1

2

3

4

3

1

4

2

1

2

3

4

3

1

4

2

SEALING

All sealing required during assembly must

be performed using neutral-curing and

non-corrosive sealants.

For example: Sikaflex®-221, silicone-free

(item no. 12DMAUSSEN).

1

2

3

4

13

13

247

282

143

13

0

27

2

19

1

181

276

215

1 Zu

luft ø 160 mm

2 Abluft

ø 160 mm

3 Außenluft

ø 160 mm

4 Fortluft

ø 160 mm

5 Gegenstromwärmetauscher

6 Abluftventilator

7 Zuluftventilator

8 Steuerung

9 Bypassklappe

10 Abluftfilter G4

11 Außenluftfilter F7

12 Kondensatwanne

13 Kabeleinführung 4 x M16 / 1 x M12

14 PTC-Elektrovorheizregister (optional)

15 Höhenverstellbare Füße

16 Kondensatstutzen

Abbildung:

LG 250 A-L (linke Ausführung)

Aufbauskizze (Stand- oder Wandmontage, linke Ausführung)

Extract air

Outdoor air

Exhaust air

Supply air

LEGEND FOR THE SYMBOLS USED

The corresponding air type for each

connection piece on the ventilation unit is

marked by means of a symbol.