SPOOLING

WIRE ROPE PREPARATION

NOTE:

The first use of your winch must be a test

run during a non-recovery situation. During this

trial run begin to recognize the sound of a steady

pull, a heavy pull, load jerking or shifting.

• Spool the wire rope.

• Wear leather gloves while spooling.

DO NOT

allow the wire rope to thread through your hand

without a glove.

•

Unwind the wire rope carefully along the floor

to avoid kinking.

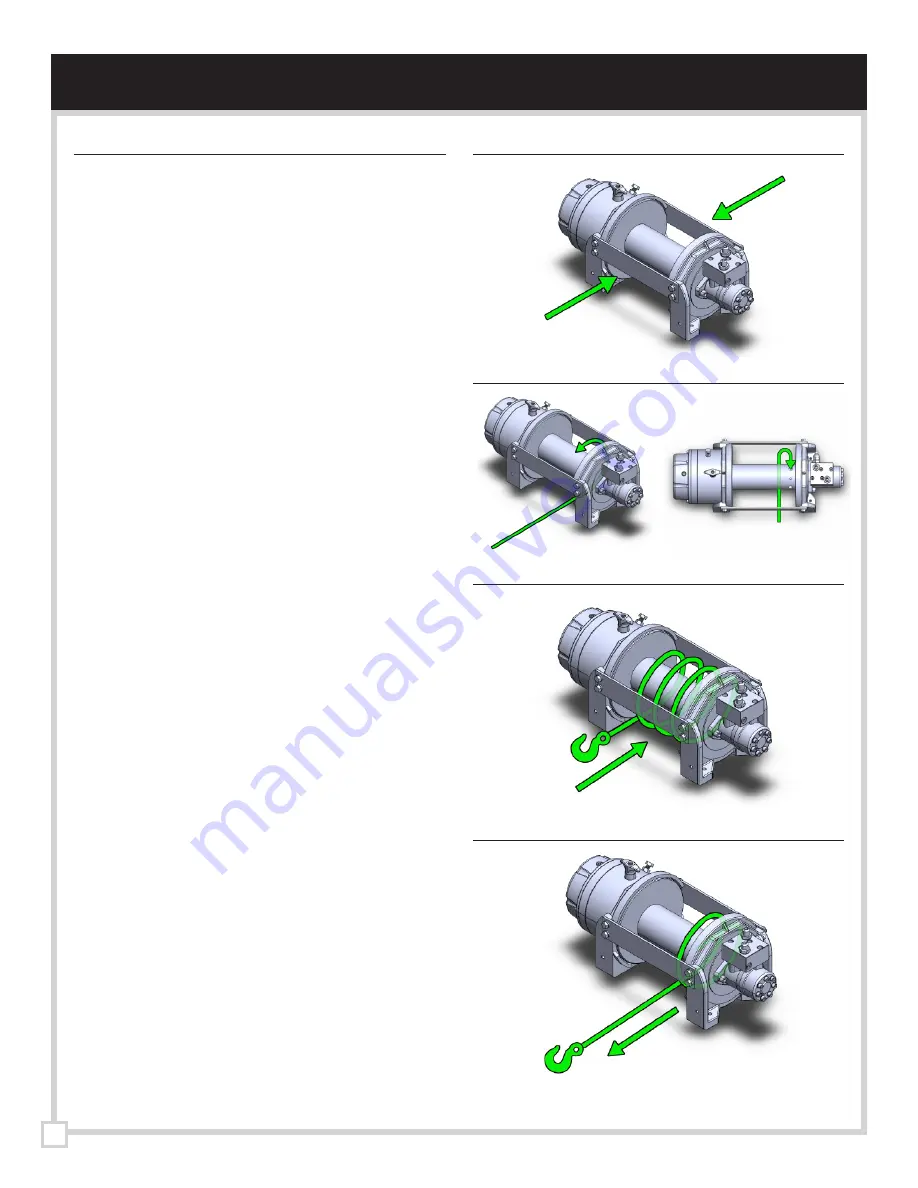

• Step 1 Make sure the winch is facing the proper

way. with the clutch side being the left side of

the winch and the motor side being the right.

(See step 1)

• Step 2 Thread the end of the cable from the

front, UNDER the drum, and up the back side

placing the end of the wire rope in to the hole at

the end of the drum. The wire rope will protrude

½”- 1”. Tighten the set screw to hold the cable in

place.

• Keep a slight load on the wire rope while

spooling. If you are facing it from the front the

drum will spin down TOWARDS you. Spool the

wire rope until the red cable is fully spooled at

approximately five wraps.

•

Under a load of 500 lbs (230 kg) finish spooling

the wire rope. This will stretch the new wire

rope and create a tight wrap around the drum.

• If there is a rope pile-up on one end of the drum,

reverse the winch to relieve the load and move

your anchor point further toward the center of

the load. Then you can re-wind for a neat layer

of the rope.

• Spool the wire rope on to the drum until the

load is recovered. During operation, make sure

the wire rope lays smoothly on to the drum

without spacing or overlapping.

STEP 1

STEP 2

STEP 3

STEP 4

Front

Back

6

Summary of Contents for PSHDH20000

Page 2: ...2 ...

Page 9: ...PSHV10000 FOOTPRINT 41 3mm 1 63 8 Ø11mm 0 43 YOU MAY REMOVE THIS PAGE 9 ...

Page 10: ...28 5mm 1 12 28 5mm 1 12 114 3mm 4 50 32 5mm 1 28 303 5mm 11 95 10 ...

Page 11: ...PSHV15000 PSHV18000 FOOTPRINT 32 5mm 1 28 8 Ø16mm 5 8 YOU MAY REMOVE THIS PAGE 11 ...

Page 12: ...28 5mm 1 12 28 5mm 1 12 114 3mm 4 50 41 3mm 1 63 291 6mm 11 48 12 ...

Page 19: ...19 ...