TPP

INSTRUCTION MANUAL

Page 14

Date rev. 28/05/13

Rev. 07

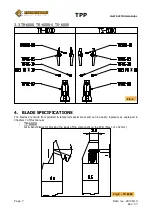

7.

SERVICING AND MAINTENANCE

7.1

NORMAL SERVICING

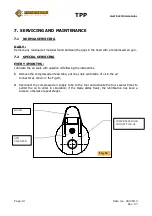

DAILY :

Remove any residual cut material found between the gaps in the head with a compressed air gun.

7.2 SPECIAL SERVICING

EVERY 4 MONTHS :

Lubricate the air seals with vaseline oil following the instructions.

1

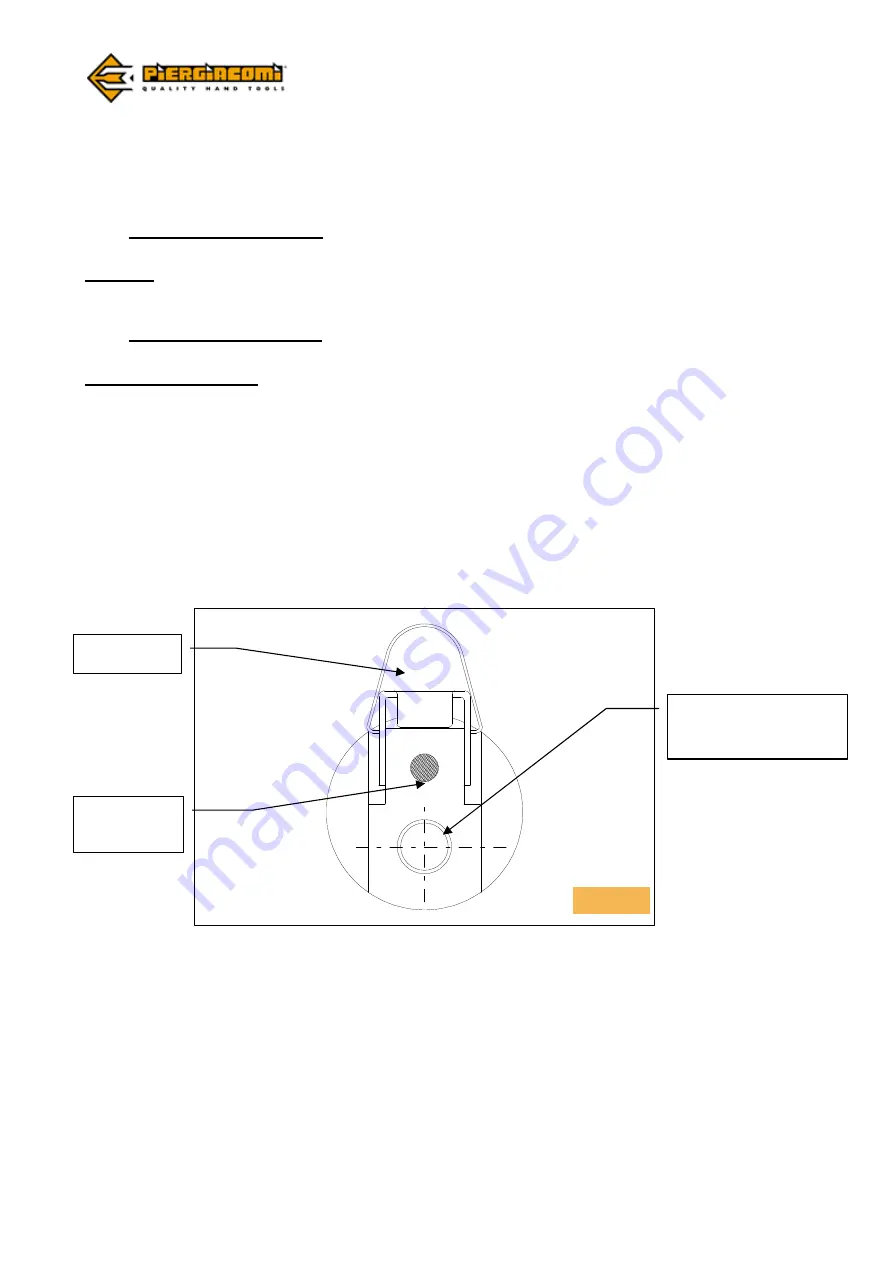

Remove the compressed air feed tube, put one cubic centimetre of oil in the air

connector as shown in the Fig.18;

2

Reconnect the compressed air supply tube to the tool and activate the tool several times to

permit the oil to enter in circulation; if the blade slides freely, the lubrification has been a

success, otherwise repeat stage 1.

HOOK

COMPRESSED AIR

CONNECTOR Ø6

AIR

SILENCER

Fig. 18