TPP

INSTRUCTION MANUAL

Page 3

Date rev. 28/05/13

Rev. 07

1.

SAFETY SYMBOLS AND RULES TO OBSERVE

Before any kind of adjustment or registration to be performed on the device,

be sure the compressed air supply system is not connected.

WARNING!!! Piergiacomi Sud S.r.l. refuses all responsibilities for any damage

caused to operators if the device’s chassis has been removed or modified;

therefore it is strictly forbidden to perform any maintenance or registration

while the device is in use.

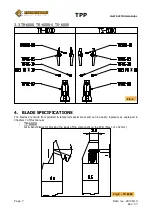

- This type of symbol on the tool means: “DO NOT PUT

YOUR HANDS” between the blades of the tool during

operation.

-

Always use protective glasses while the tool is operating.

-

Turn off the compressed air supply each time the tool is lean on

without using it.

-

After use place the tool in a safety location and disconnect it from

the compressed air supply system.

-

Observe and carry out the indications and warnings shown on the

special stickers on the tool.