TPP

INSTRUCTION MANUAL

Page 5

Date rev. 28/05/13

Rev. 07

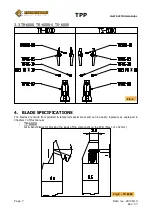

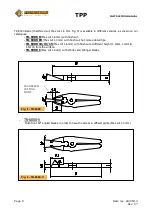

2.2 TP-6000 - TP-6000-15 - TS-6000

Those who work in the electronics sector frequently have the problem of blocking the components on the

printed circuit board before and during the soldering phase. In order to solve the problem, Piergiacomi

has designed and produced these tools, the TP-6000, which cuts the component leads and bends them

so as to fix them firmly in place to the board. The operator that will later perform the soldering phase will

therefore not have that troublesome problem of components that have been displaced or in the worst

case become loose and fallen off the board.

The TP-6000 or TP-6000-15 proves to be an enormously special tool as it manages to carry out two

functions in one operation and furthermore has the advantages of being a lightweight and reduced costs

pneumatic tool.

This is the basis of our philosophy and our product has been designed to meet both performance and

safety requirements.

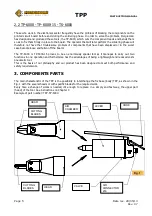

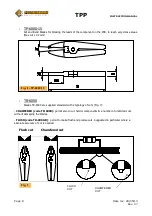

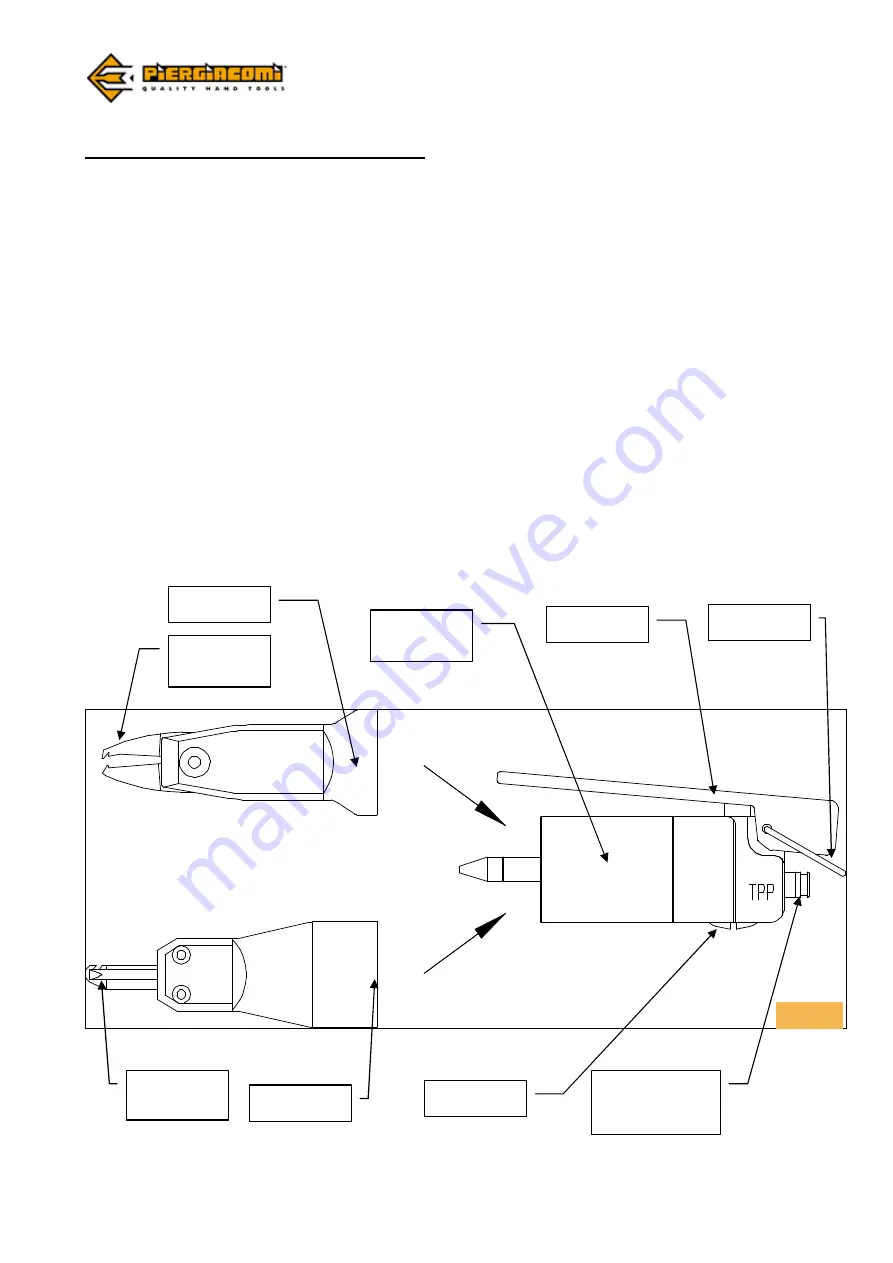

3. COMPONENTS PARTS

The main characteristic of the TPP is the possibility to interchange the fix base (body) TPP, as shown in the

Fig. 1 with the several heads or with specific blades for the required work.

Every time a change of works is needed, it’s enough to replace, in a simply and fast way, the upper part

(head) of the tool. See instructions on Chapter 7.

Example of part number: TPP-TP-6000

VALVE

HOOK

AIR

CONNECTOR

Ø6

LEVER

AIR

CHAMBER

HEAD

HEAD

CUTTING

BLADES

CUTTING

BLADES

Fig. 1