14

| HR250 Manure Spreader 2020 | Pik Rite Inc.

PREPARING THE TRACTOR

APPROVED TRACTORS, MODEL HR250

Row Crop Tractors with 60 HP PTO rating or larger are approved for operation with the HR250 Spreader.

Utility Tractors are

NOT RECOMMENDED

because of drawbar weight limitations and the inability to ballast the

tractor enough to meet requirements for towing.

A drawbar support is required on any tractor with a drawbar size of no less than 1-1/2 x 3 in.

Tractor hydraulic oil reservoir must have capacity for 3.4 U.S. gal. net draw for a spreader with an endgate or 3.1

U.S. gal. without an endgate.

Tractor standby hydraulic pressure must be between 1500 psi and 2250 psi.

One selective control valve is required to operate the spreader.

A second selective control valve is required to operate the endgate.

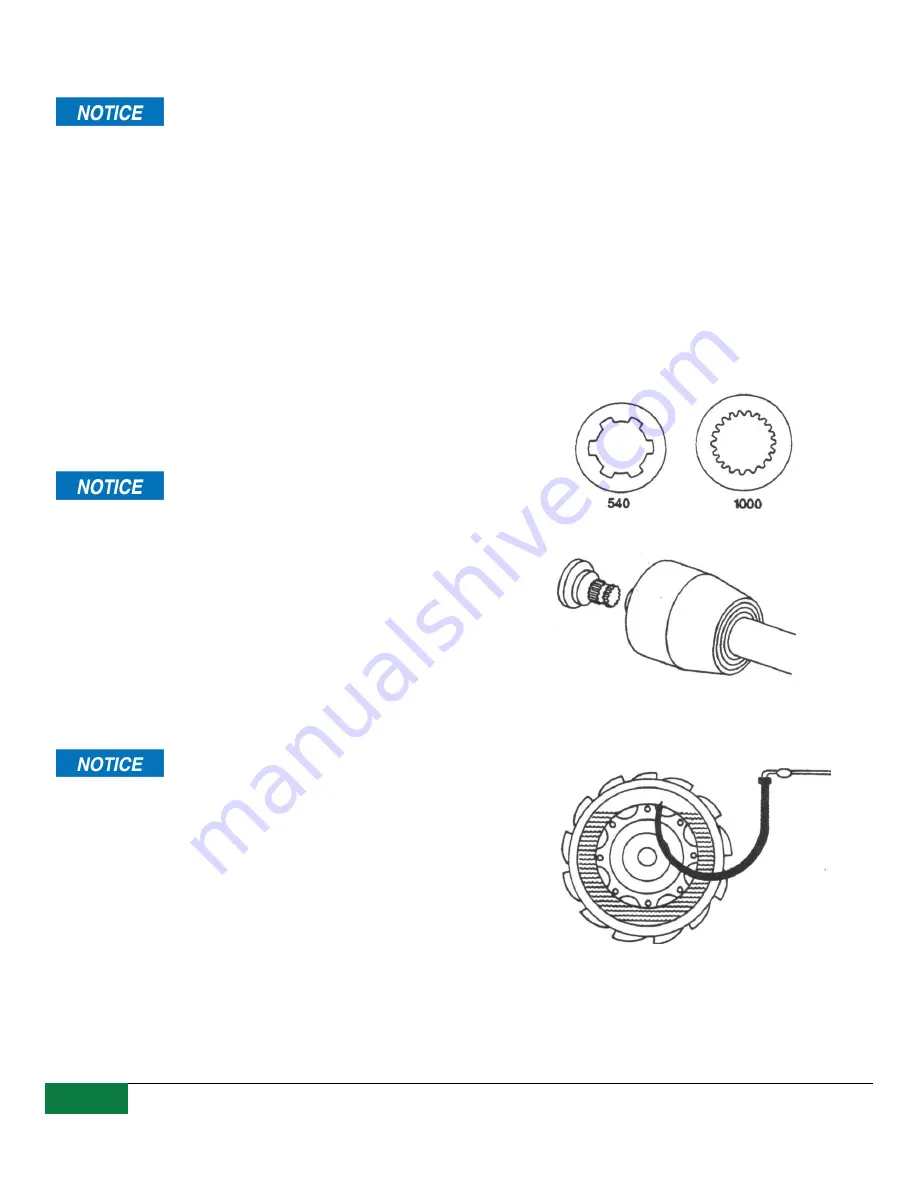

CHOOSING CORRECT PTO SPEED

MODEL – HR250 –

540 RPM ONLY

Drive components can be damaged.

Under no circumstances should a machine equipped for 540 rpm

PTO be operated by a tractor equipped with 1000 rpm PTO.

Nor should a 1000 rpm PTO machine be operated with a

tractor equipped with 540 rpm PTO.

BALLASTING THE TRACTOR

Do not tow loads that weigh more than twice the

tractor weight.

(See Recommended Maximum Towing Speed in Transport section.)

To ensure proper stability, adjust ballast and wheel

spacing according to tractor operator’s manual.

Summary of Contents for HydraRam HR250

Page 5: ...Pik Rite Inc HR250 Manure Spreader 2020 5 TABLE OF CONTENTS ...

Page 6: ...6 HR250 Manure Spreader 2020 Pik Rite Inc ...

Page 35: ...Pik Rite Inc HR250 Manure Spreader 2020 35 7215 1 01 MAIN FRAME AND SIDE PANELS ...

Page 39: ...Pik Rite Inc HR250 Manure Spreader 2020 39 7215 1 04 PUSHER ...

Page 43: ...Pik Rite Inc HR250 Manure Spreader 2020 43 7215 1 07 HUBS AND SPINDLES ...

Page 47: ...Pik Rite Inc HR250 Manure Spreader 2020 47 7219 1 09 OPT WEIGHT SCALE SYSTEM 3 POINT DG400 ...

Page 51: ...Pik Rite Inc HR250 Manure Spreader 2020 51 7215 2 01 DRIVELINE FRONT 1 3 8 CV ...

Page 53: ...Pik Rite Inc HR250 Manure Spreader 2020 53 7215 2 02 DRIVELINE REAR WITH CLUTCH ...

Page 55: ...Pik Rite Inc HR250 Manure Spreader 2020 55 7215 2 03 DRIVELINE MID SHAFT AND SHIELDS ...

Page 61: ...Pik Rite Inc HR250 Manure Spreader 2020 61 7215 2 05 GEARBOX VERTICAL BEATERS ...

Page 65: ...Pik Rite Inc HR250 Manure Spreader 2020 65 7215 3 03 CYLINDER SLIDING FLOOR ...

Page 67: ...Pik Rite Inc HR250 Manure Spreader 2020 67 7215 3 04 CYLINDER PUSHER ...

Page 69: ...Pik Rite Inc HR250 Manure Spreader 2020 69 7215 3 05 CYLINDER ENDGATE ...

Page 71: ...Pik Rite Inc HR250 Manure Spreader 2020 71 7219 3 06 OPT FLOW CONTROL ...

Page 73: ...Pik Rite Inc HR250 Manure Spreader 2020 73 7219 3 07 OPT REMOTE FLOW CONTROL ...

Page 75: ...Pik Rite Inc HR250 Manure Spreader 2020 75 7215 4 01 OPT SAFETY CHAIN ...

Page 77: ...Pik Rite Inc HR250 Manure Spreader 2020 77 7215 4 02 ACCESSORIES ...

Page 79: ...Pik Rite Inc HR250 Manure Spreader 2020 79 7215 4 03 OPT LIGHT ASSEMBLY LED ...