3.3.

4.1

3.3.

4.2

Insert pin Figure 2 [1] into Frame 21 lower lug Figure 2 [4]. If there are any difficulties fitting this pin, consult

Pilatus Customer Support for further advice.

3.3.

4.3

Install Washer (Pt.No. 6107806-09) Figure 2 [5] and Knurled Nut (Pt.No. 6107806-08) Figure 2 [6] onto the

end of pin Figure 2 [2] and hand tighten. This action locates the jig in the correct fore-aft position.

3.3.

5

Install the Jig Assembly RH Figure 2 [7] to the RH fuselage lugs as follows:

3.3.

5.1

3.3.

5.2

Insert pin Figure 2 [1] into the Frame 21 lower lugs Figure 2 [4]. If there are any difficulties fitting this pin,

consult Pilatus Customer Support for further advice.

3.3.

5.3

Install Washer (Pt.No. 6107806-09) Figure 2 [5] and Knurled Nut (Pt.No. 6107806-08) Figure 2 [6] onto the

end of pin Figure 2 [2] and hand tighten. This action locates the jig in the correct fore-aft position.

3.3.

6

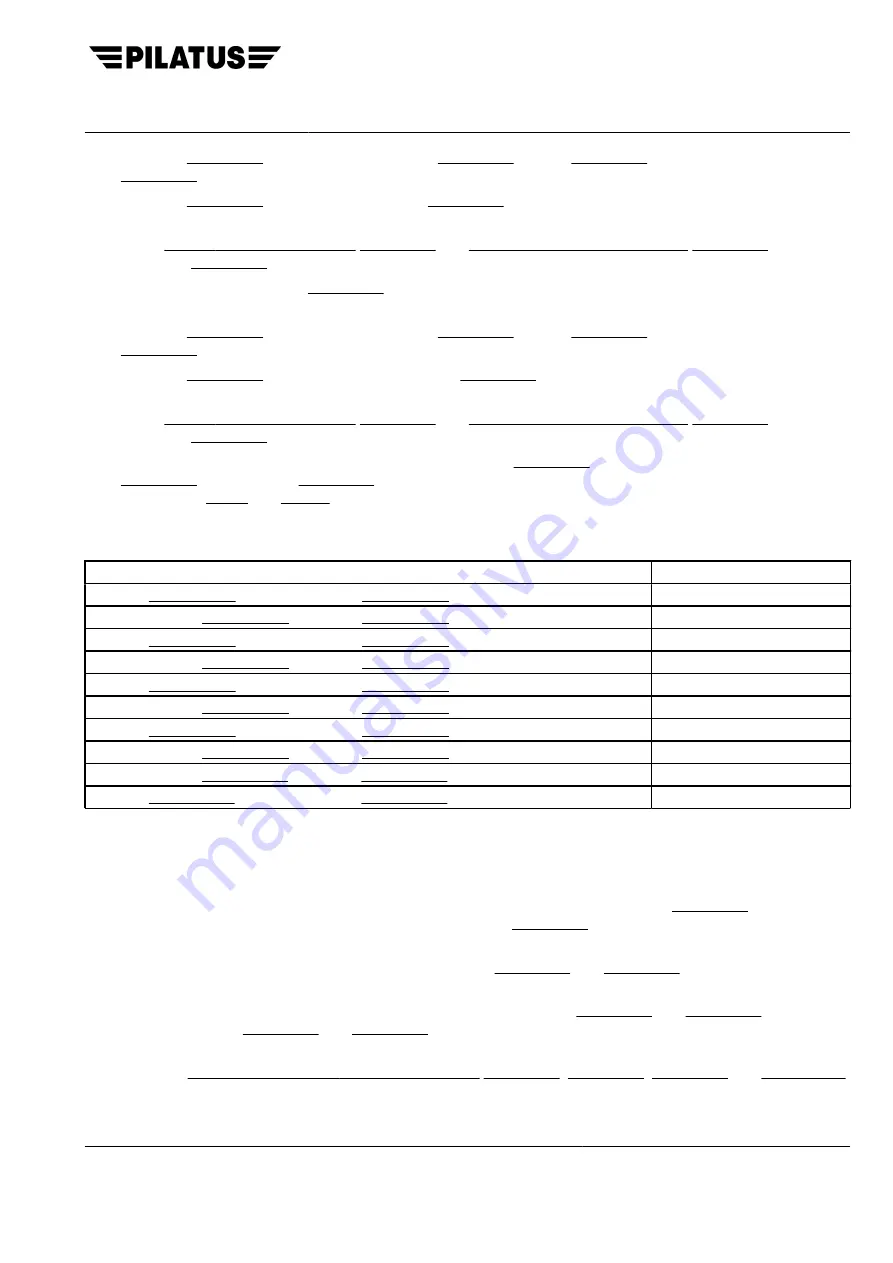

Measure the gaps between the LH and RH Jig Assemblies Figure 3 [1] and the fuselage lugs on Frame 21

Figure 3 [2] and Frame 24 Figure 3 [3]. Check that the measurements are compliant with the information

contained in Fig. 3 and Table 6. Any deviation from these dimensions indicates local bending of lugs has

occurred.

Table 6 Lug Gap Dimensions

Lug

Gap Dimension (mm)

Jig Assy Figure 3 [C1] - Frame 21 Upper Figure 3 [C2]

2,5 +0.65 / -0,80 mm

Frame 21 Upper Figure 3 [C2] - Jig Assy Figure 3 [C3]

4,6 +0.40 / -0,30 mm

Jig Assy Figure 3 [C3] - Frame 21 Upper Figure 3 [C4]

2,5 ± 0,10 mm

Frame 21 Upper Figure 3 [C4] - Jig Assy Figure 3 [C5]

4,5 +0,70 / -0,55 mm

Jig Assy Figure 3 [D1] - Frame 21 Lower Figure 3 [D2]

2,5 +0,95 / -1,10 mm

Frame 21 Lower Figure 3 [D2] - Jig Assy Figure 3 [D3]

4,5 +0,70 / -0,60 mm

Jig Assy Figure 3 [D3] - Frame 21 Lower Figure 3 [D4]

2,5 ± 0,40 mm

Frame 21 Lower Figure 3 [D4] - Jig Assy Figure 3 [D5]

4,5 +1,00 / -0,85 mm

Frame 24 Lower Figure 3 [E1] - Jig Assy Figure 3 [E2]

3,0 +0,50 / -0,50 mm

Jig Assy Figure 3 [E2] - Frame 24 Lower Figure 3 [E3]

3,0 +0,50 / -0,50 mm

3.4 Wing Alignment Checks

The following dimensional checks are to make sure that the fuselage lugs will allow the wings to align

correctly:

3.4.

1

Measure the gap between the face of the LH and RH Jig Assembly upper aft fitting Figure 3 [1] and the

corresponding face on the LH and RH Frame 24 upper lug Figure 3 [3]. The dimensions must be 1 mm ±0,5

mm. If the gap is outside of these limits, consult Pilatus Customer Support for further advice.

3.4.

2

Check the roll attitude of the LH and RH jigs at surfaces Figure 4 [5] and Figure 4 [6]. These surfaces must be

90 degrees ±0,05 degrees to the top of Frame 21.

3.4.

3

Check the longitudinal level of the LH and RH jigs between surfaces Figure 4 [1] and Figure 4 [4], and then

between surfaces Figure 4 [2] and Figure 4 [3] respectively. These surfaces must be within 0,125 degrees of

horizontal, and within 0,25 degrees of each other.

3.4.

4

Insert the Conical Centre Fittings (Pt.No. 6107806-20) Figure 4 [7], Figure 4 [8], Figure 4 [9] and Figure 4 [10]

into the holes on the lower side of each jig assembly.

PC-12/47E AMM Doc No 02300, ISSUE 01 REVISION 27 MSN 545, 1001-1719, 1721-1942

12-B-AM-00-00-00-I

UNCLASSIFIED

Effectivity: All

12-B-05-50-07-00A-282A-A

UNCLASSIFIED

19.11.2019 Page 5