Component Maintenance Manual

EFFECTIVITY: ALL

21-00-22

Page

5005

JULY 21, 2011

SUBTASK 21-00-38-21-002

7.2

Evaporator Module Inspection Schedule:

NOTE

: This is the recommended visual inspection schedule for the Evaporator Module Assembly.

Adherence to this schedule will ensure that all components of the assembly are in accordance with the

manufacturer’s specifications and is necessary to detect structural failure, deterioration or damage, and to

determine the need for corrective action.

7.2.1

If any component listed in this schedule requires cleaning, refer to Cleaning Procedure

(Section 6).

7.2.2

If any component listed in this schedule requires repair and/or replacement, refer to Repair

(Section 8).

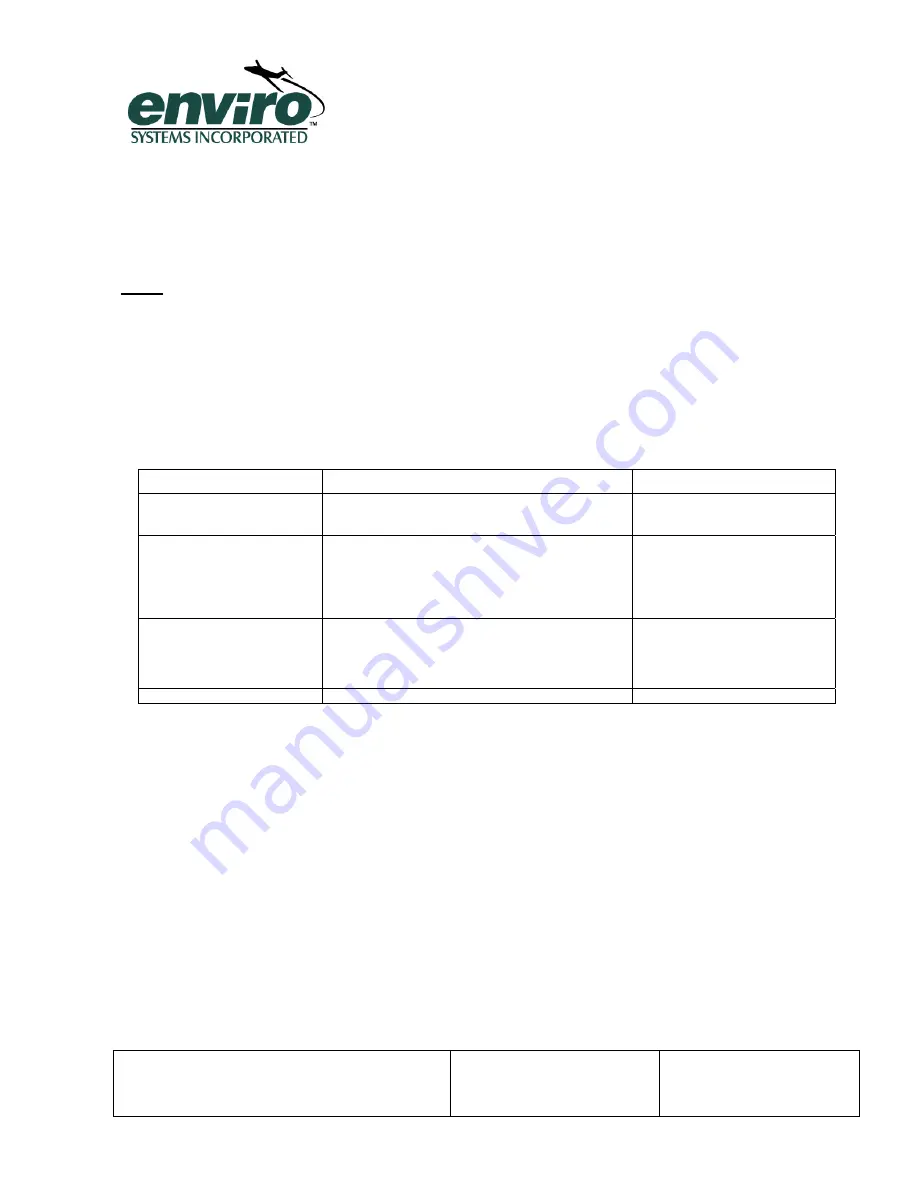

Component Type

Inspection

Required

Times

*Evaporator Coil Assembly

Inspect refrigerant plumbing for leakage

Inspect coil fins for cleanliness and damage

Inspect cold air ducting for leaking cracks or damage

12 Months

Evaporator housing Assembly

*Shroud Assembly

*Escutcheon

*Water Deflector

Inspect seam between shroud assembly and

escutcheon for signs of separation and condensate

leakage.

Inspect for cleanliness and damage/integrity.

Inspect condensate drain, making sure hole is clear

and secure.

12 Months

Blower Assembly

*Blower Motor

*Blower Wheel

*Blower Scroll

Inspect for cleanliness and damage/integrity

Verify that blower wheel is clean and operates vibration

free.

12 Months

Blower Motor must be removed

and replaced between 4900-5100

hours in service

Expansion Valve

Inspect for cleanliness and damage/integrity

12 Months

Table 3.6 Forward and Aft Evaporator Module Inspection Schedule