Operating instructions (translation from original IT)

Cod. OQ7_5ARG078EN

Emiss. 18-07-08 Rev. 5 - Agg. 20-04-16

26

13

FIRST START-UP

The first start-up of the compressor (operative test) must obligatorily be carried out by a specialized technician.

Ask the testing technician to fill in the R.C.R. form at the end of the manual. Filling in this form allows you to be sure that a complete

test has been performed and, in the event of malfunctions of any kind, faster and more effective action can be taken under guarantee.

ON-OFF COMPRESSOR

These compressors are provided with a safety device as regards the

direction of rotation

. Running the compressor with the wrong

direction of rotation may damage it seriously and cause the leakage of oil from the intake valve.

To make the first start-up, after installation, turn on the power supply to the electric panel.

If the phases are inverted, the following message will appear on the board display: “INCORRECT ROTATION”.

Proceed as follows:

1.

Switch off the power;

2.

Exchange the connections of the two phases of the compressor power supply line;

3.

Restore power. Consequently also the direction of rotation of the electric fan will be correct.

4.

Reset the alarm by pressing the “RESET” button and start the machine.

If the phases are correct no alarm appears on the display and the machine can be started.

COMPRESSOR ACTIVATED BY AN INVERTER

Compressors with an inverter are equipped with an electronic system to control the

absorbed power

and the

motor temperature

, in

any case it is important to take the greatest care during the

first start-up

to avoid very serious damage to the compressor itself.

To make the first start-up, after installation, turn on the power supply to the electric panel, press the “Start” key and check that the

electric fan is turning in the correct direction, comparing it with the direction indicated by the sticker on the structure. If the direction

is incorrect, proceed as follows:

a)

switch off the machine

b)

switch off the power

c)

exchange the connections of two phases of the electric fan power supply

d)

restart the machine.

FOR THE FIRST START-UP CONSULT THE SPECIFIC INVERTER MANUAL SUPPLIED WITH THE

DOCUMENTATION.

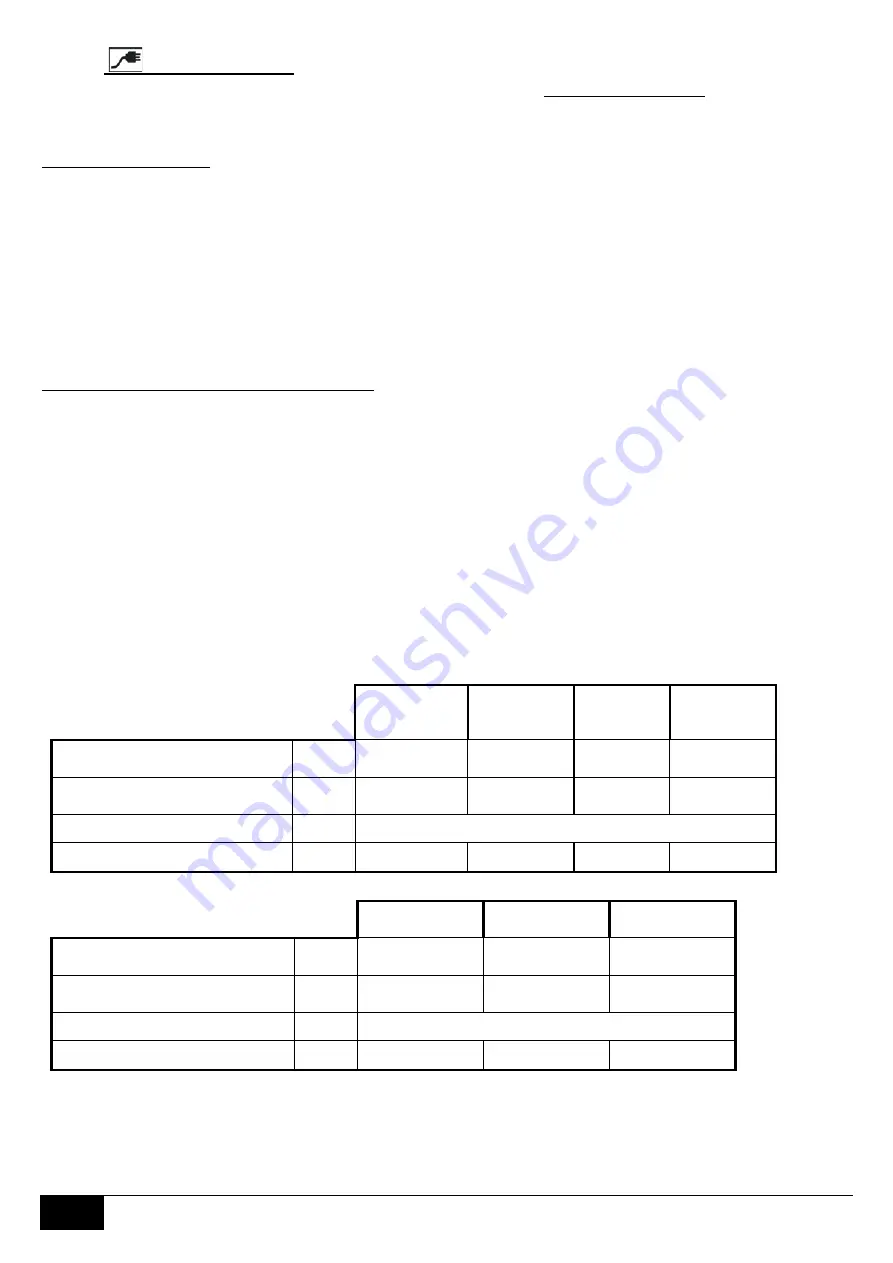

To change the fuses and the electric cables, refer to the following table.

400/50

NEWTON

1307

EDISON

1309 DV

NEWTON

1311

NEWTON

EDISON DV

1315

Input cables minimum section (*)

mm²

10

10

10

16

Electronic board fuses

N° x A

1 x 2

1 x 2

1 x 2

1 x 2

Electric panel fuses

N° x A

Check wiring diagram

Auxiliary / electronic panel voltage

V

110 / 15

110 / 15

110 / 15

110 / 15

230/60

NEWTON

1307

NEWTON

1311

NEWTON

1315

Input cables minimum section (*)

mm²

16

16

25

Electronic board fuses

N° x A

1 x 2

1 x 2

1 x 2

Electric panel fuses

N° x A

Check wiring diagram

Auxiliary / electronic panel voltage

V

110 / 15

110 / 15

110 / 15

(*) Neutral connection if there is a dryer or heater present.