Operating instructions (translation from original IT)

Cod. OQ7_5ARG078EN

Emiss. 18-07-08 Rev. 5 - Agg. 20-04-16

44

24

ROUTINE MAINTENANCE

By routine maintenance we mean all the activities aimed at maintaining the conditions of use and operation of the

equipment with various types of intervention performed by the operator.

Use only original parts for replacement.

24.1

PRECAUTIONS DURING MAINTENANCE

Maintenance and repairs must be carried out only by sufficiently trained personnel, under the supervision of a technician qualified to

do the job.

1. Use only suitable tools for performing maintenance and repairs.

2. Use only original spare parts.

3. All maintenance jobs that are not routine supervision must be started only when the compressor is at a standstill. Ensure that the

unit cannot be started accidentally.

4. Before removing any component under pressure, efficiently isolate the unit from any source of pressure and discharge pressure

from the whole system.

5. Never use inflammable solvents or carbon tetrachloride to clean the parts. Take the necessary safety precautions against the toxic

vapours of fluids used for cleaning purposes.

6. Observe the strictest standards of cleanliness during maintenance and repair jobs. Protect the parts against dirt, keeping them

covered, and plug the openings with clean rags, paper or covers.

7. Never perform welding, or other operations that require heat, near the oil system. In particular the oil tanks must be completely

cleaned before these operations can be carried out on them, for example by washing them with steam.

Never perform welding or make alterations of any kind on tanks under pressure.

8. Ensure that no tools, loose parts or cloths are left lying on the compressor, on the motor or on the moving parts.

9. Before leaving the unit to be started up after maintenance or overhauling, check that the pressures, the temperatures and the

settings are correct and that the control devices and safety stops work correctly.

10. Protect the motor, the electric parts and the regulation system components, etc. against infiltrations of humidity, for example when

cleaning the unit with steam.

11. Maintain the noise level as specified. never remove sound-deadening material from the panels.

12. Never use caustic solvents which may damage the materials used in the air system, for example transparent polycarbonate

containers.

13. When handling refrigerating substances the following safety precautions must be taken:

a. Do not inhale the refrigerant vapours. Ensure that the area where you are working is sufficiently ventilated.

b. Always wear special gloves. If any splashes of refrigerating substance get on your skin, wash immediately with water. For no

reason should you work on the machine without protective garments.

c. Always wear safety goggles.

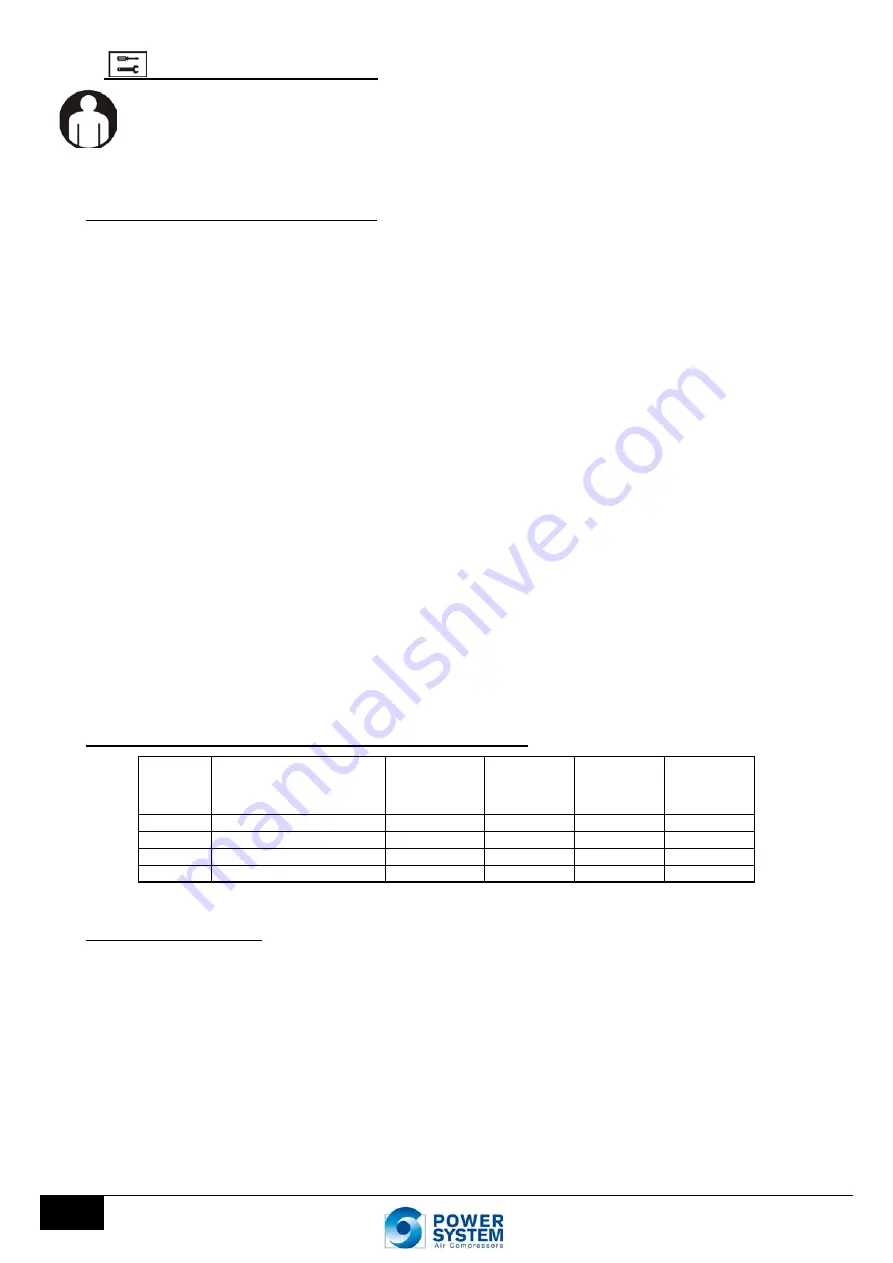

24.2

LIST OF SPARE PARTS FOR ROUTINE MAINTENANCE PS1300

CODICE

DESCRIZIONE

NEWTON

1307

EDISON

1309 DV

NEWTON

1311

NEWTON

EDISON DV

1315

490009

Air-oil separator cartridge

1

1

1

1

480039

Air filter cartridge

1

1

1

1

470020

Oil filter cartridge

1

1

1

1

290003

Suction prefilter panel

1

1

1

1

CODE 600000007 Oil RotEnergyPlus (18.5 LT tank)

24.3

OIL CHARACTERISTICS

An oil for screw compressors with oil injection must be used, with the addition of oxidation inhibitors, and having anti-foam

and anti-wear properties.

Never mix oils of different makes or types.

If you want to change the make of oil, stop the compressor and depressurize it, completely drain off the existing oil in

the compressor and change the oil filter, then fill the tank with the new oil.