7. Machine Maintenance

Danger of injury!

Carry out the maintenance work only if the MAIN SWITCH is off or if the machine is disconnected from the mains.

Care and maintenance is absolutely necessary to maintain the functionality of the machine and its components. This includes: check

and adjustment of band saw guide heads • cleaning • metal chips removal • removing metal chips from the internal part of the band

saw arm • coolant replacement • lubrication of sliding surfaces and bearings • checking of supply lines for damage • vice checks •

screw connection checks • limit switch checks

Check protective devices

Check the protection devices for possible damages and faults prior to the start of everyday work.

Check power cable

Check in regular intervals, at least once a week: integrity of electric installation • integrity of connections and relief from

pulling

7.1. Cleaning

Clean the machine in regular intervals (always at the end of the shift, or if required, during the shift). To clean the machine, use

appropriate detergents. Do not use solvents (e.g. nitro diluent). Do not use compressed air! Compressed air would blow delicate

chips and dirt particles under sliding elements or endanger the health of personnel by flying particles.

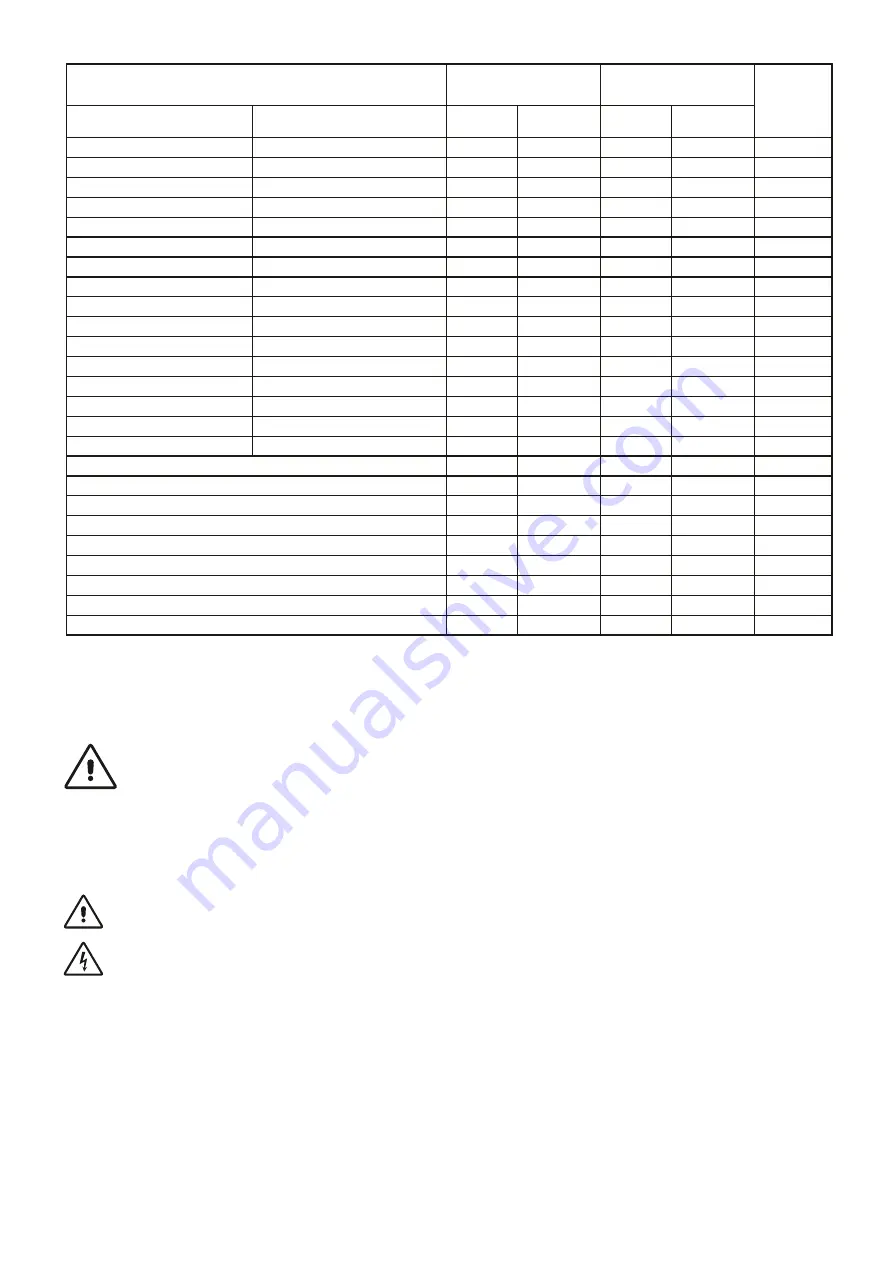

11 107 - 11 110

11 500 - 11 600 / 12 020 - 12 060

13 250 / 14 260 / 15 260

14 100 / 15 220

14 220 / 15 124

17 020 - 17 042

17 115

17 253 - 17 255

19 150 / 19 192 - 19 312

19 422 / 19 452 / 19 721 / 19 740

19 436

19 662

19 721

19 802 - 19 860

INCONEL, HASELLOY, NIMONIC, INCOLOY

Heat-treated steel

Cast steel

Grey cast iron

Copper, bronze, tin bronze

Red bronze

Aluminium bronze

Aluminium alloy castings

Al 99%, thermoplastics, plastics

11 301 - 11 420 / 12 010 - 12 020

19 063 - 19 083 / 15 142 / 16 142

ČSN

Material

Cooling

oil

volume

(%)

10-15

10

10-15

5-10

3

10-15

10-15

5-10

15

5-10

5-10

3

do not

15-20

5

3

15-20

5

40

25

3

10

10-15

do not

do not

Arm descent speed

into the cut

(mm/min)

ø 100-330 mm

55-20

30-20

35-25

28-15

28-15

55-30

12-4

18-2

6-1

30-25

20-8

21-10

14-5

4-2

16-6

21-10

4-2

23-12

55-25

140-55

85-55

70-45

70-45

55-30

140-55

ø 0-100 mm

190-60

125-35

125-38

125-30

125-30

190-60

75-15

100-20

40-7

125-35

120-25

90-23

62-15

25-5

70-1

90-23

25-5

76-25

190-60

450-150

300-90

230-75

230-75

190-60

450-150

Recommended blade speed

(m/min)

ø 100-330 mm

70-90

40-70

50-70

40-60

30-60

60-80

30-40

30-50

30

40-70

30-60

30-50

30-40

30

30

30-50

30

30-40

30-60

80-90

60-90

60-90

30-60

30-70

50-80

ø 0-100 mm

70-90

50-80

60-90

50-70

50-70

60-90

40-50

40-50

30-40

60-90

50-70

40-60

30-40

30

30-40

40-60

30

40-50

30-70

80-90

70-90

70-90

40-70

40-80

50-90

In general

Free-cutting steel

Structure/construction steel

Cementing steel

Spring steel

Bearing steel

Alloy steel

NIRO steel

Valve steel

Heat-resistant steel

Refining steel

Non-alloy tool steel

Alloy steel

Hammer steel

Nitriding steel

Tool steel for hot processing

High speed steel

Summary of Contents for ARG 300 plus S.A.F.

Page 2: ......