PSEN ma2.1p-11/-31

Operating Manual PSEN ma2.1p-11/-31

22191-EN-02

11

}

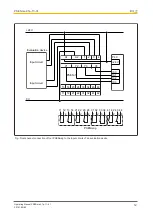

PNOZmulti for safety gate monitoring

Configure the switch in the PNOZmulti Configurator with switch type 2.

}

PSS for safety gate monitoring with standard function block SB064, SB066 or

FS_Safety Gate

}

PSSuniversal PLC for safety gate monitoring with function block FS_SafetyGate

A full list of the certified Pilz evaluation devices (type examination certificate) is available in

the download area (http://www.pilz.com/support/downloads).

The correct connection to the respective evaluation device is described in the operating

manual for the evaluation device. Make sure that the connection is made in accordance

with the specifications in the operating manual for the selected evaluation device.

Defined properties of evaluation devices:

}

2-channel with feasibility monitoring

}

Open circuit monitoring of the safety switch is performed

}

The inputs and outputs of the evaluation device must fulfil the requirements of

IEC 61131

}

Technical data of the evaluation device must fulfil the requirements in the

of PSEN ma2.1p-11/-31

–

Always comply with the max. switching current safety contacts of PSEN

ma2.1p-11/-31.

}

Outputs at the evaluation device must only be switched on again when both reed con-

tacts at the safety switch have been opened and closed (partial operation lock)

INFORMATION

Risk time in accordance with DIN EN 60947-5-3

The risk time is made up of the reaction time of the sensor (see

) and the processing and delay times of the evaluation

device (s. operating manual for the relevant evaluation device).