Connection to control systems and evaluation devices

Operating Manual PSEN ml sa 1.1/2.1/2.2, PSEN ml DHM

1005457-EN-02

| 37

6.5

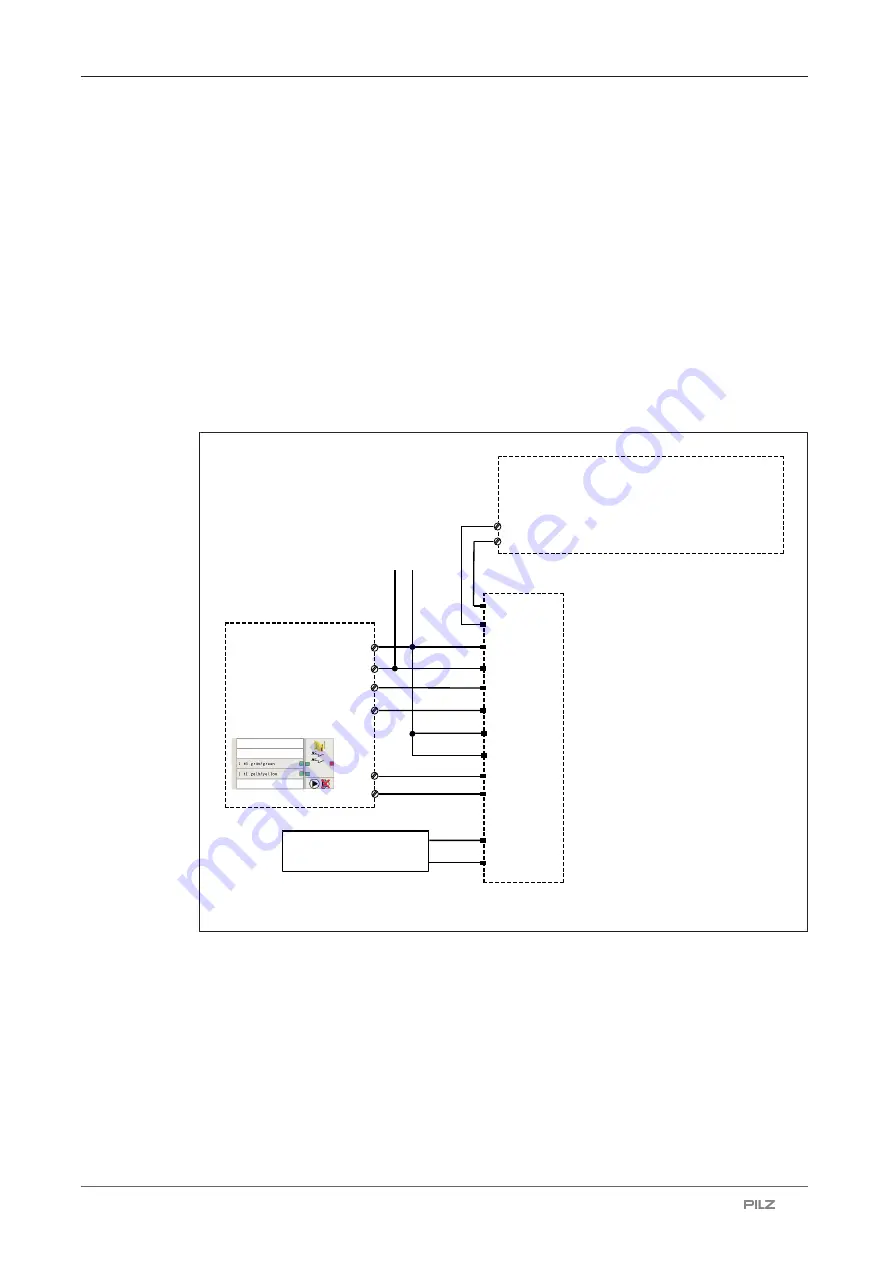

Connection to Pilz evaluation devices

The safety switch can be connected to Pilz evaluation devices.

Suitable Pilz evaluation devices are, for example:

}

PNOZmulti for safety gate monitoring

Configure the switch in the PNOZmulti Configurator with switch type 3.

}

PSSuniversal PLC for safety gate monitoring with function block FS_SafetyGate

The correct connection to the respective evaluation device is described in the operating

manual for the evaluation device. Make sure that the connection is made in accordance

with the specifications in the operating manual for the selected evaluation device.

Connection to PNOZmulti is illustrated by way of example.

Connection example with PNOZmulti and Safety Device Diagnostics

A1

A2

I0

I1

A1

A2

Y32

Y1

12

22

5

1

4

6

8

3

2

9

PNOZmulti

PSEN ml

0 V

24 V

S31

S41

O2 (FS)

O1 (FS)

Rx

10

7

S11

S21

Tx

32

42

11

12

Activation of guard locking via SDD ES module

following PSEN ml