PSEN opII3H Series

Operating Manual PSEN opII3H Series

1003503-EN-05

| 33

– The clamps for connection to the evaluation device must be kept in a locked control

cabinet. This prevents unauthorised modifications.

}

Ensure compliance with permissible cable bending radii (see

Connector pin assignment

Transmitter and receiver electrical connections are made with M12 connectors. These con-

nectors are located on the bottom of the transmitters and receivers.

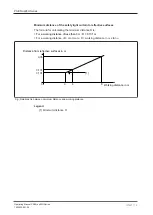

5-pin connector on the transmit-

ter

PIN

Assignment

Cable colour

1

2

3

4

5

1

uncoded: +24 VDC

brown

A-coded: +24 V DC

B-coded: 0 V DC

2

Reserved

white

3

0 VDC

blue

4

Reserved

black

5

uncoded: +24 VDC

grey

A-coded: 0 V DC

B-coded: +24 V DC

5-pin connector on the receiver

PIN

Assignment

Cable colour

1

2

3

4

5

1

uncoded: +24 VDC

brown

A-coded: +24 V DC

B-coded: 0 V DC

2

OSSD 1

white

3

0 VDC

blue

4

OSSD 2

black

5

uncoded: +24 VDC

grey

A-coded: 0 V DC

B-coded: +24 V DC

}

Ensure that the wiring has been performed according to the truth table.

Receiver/transmitter

Pin

uncoded

A-coded

B-coded

Receiver

1

24 V

24 V

0 V

3

0 V

0 V

0 V

5

24 V

0 V

24 V

Transmitter

1

24 V

24 V

0 V

3

0 V

0 V

0 V

5

24 V

0 V

24 V

Truth table for checking the pin assignment