PNOZ X10.11P

Operating Manual PNOZ X10.11P

20820-EN-13

| 22

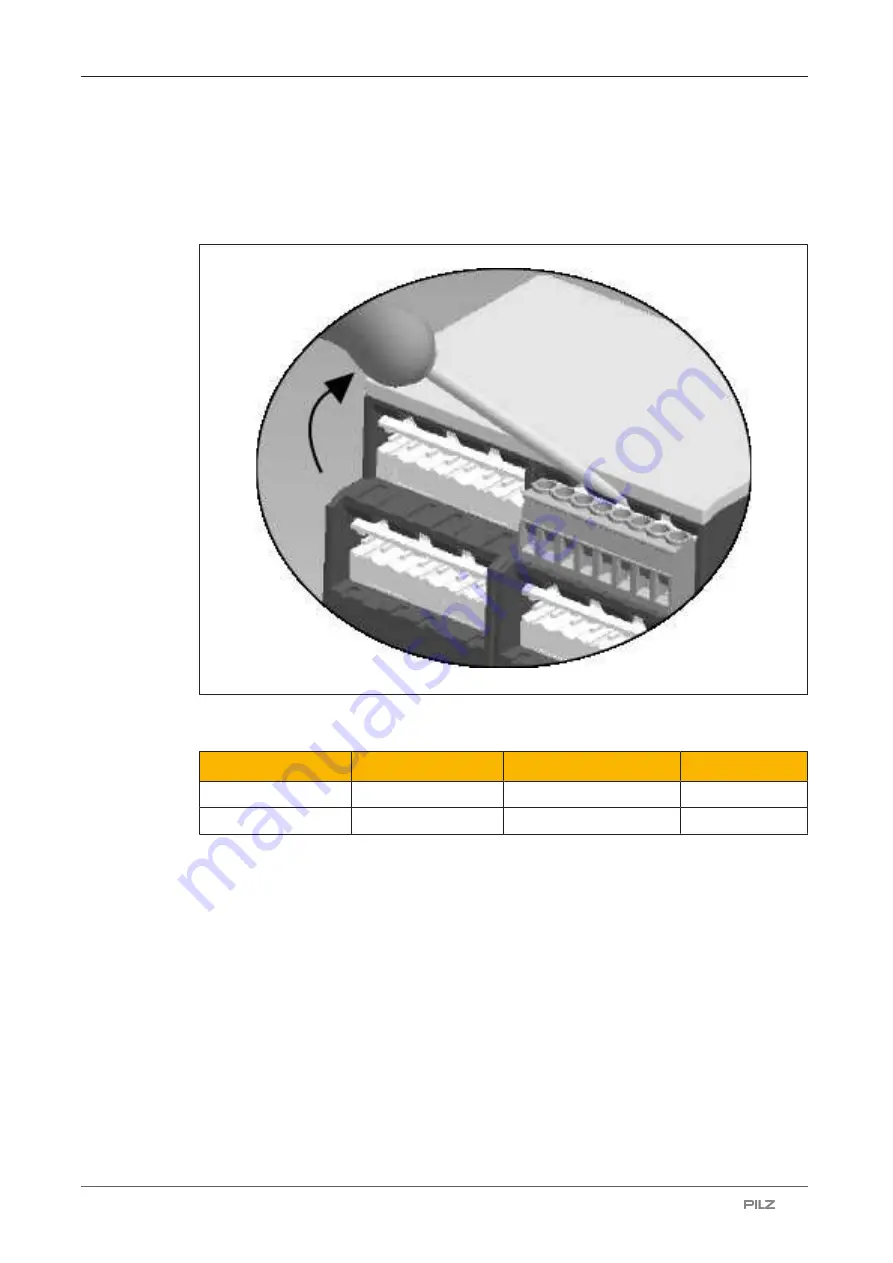

Remove plug-in terminals

Procedure: Insert the screwdriver into the housing recess behind the terminal and lever the

terminal out.

Do

not

remove the terminals by pulling the cables!

Order reference

Product type

Features

Connection type

Order no.

PNOZ X10.11P C

24 V DC

Spring-loaded terminals

787750

PNOZ X10.11P

24 V DC

Screw terminals

777750

EC declaration of conformity

This product/these products meet the requirements of the directive 2006/42/EC for ma-

chinery of the European Parliament and of the Council. The complete EC Declaration of

Conformity is available on the Internet at www.pilz.com/support/downloads.

Representative: Norbert Fröhlich, Pilz GmbH & Co. KG, Felix-Wankel-Str. 2, 73760 Ost-

fildern, Germany