Function description

Operating Manual PMCprimo MC

1003813-EN-03

| 19

4.1.4

Digital outputs

The device has 16 single-pole digital outputs (X40b: Pin 5 … 8 and Pin 13 … 16, X50c:

Pin 5 …8 and Pin 13 … 16).

Signals at the output

}

"0" signal (0 V) at the output:

– Output is high impedance

– No current to the load

}

"1" signal (+24 V) at the output:

– Output is low impedance

– Current is supplied to the load

– The maximum current strength per output is 0.5 A.

All digital outputs are protected against short circuit and overload.

The outputs can be used to connect relays, valves or inputs from another controller, for ex-

ample.

4.1.5

Interfaces

4.1.5.1

Overview

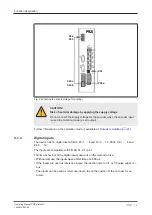

The motion controller PMCprimo MC has various fieldbuses for communication with the

periphery. These are available on RJ45 sockets on the front of the device or 9-pin D-Sub

connections. The interfaces are suitable for the following applications:

}

CANopen

– Real-time capable networking between CAN devices and the motion controller

– Suitable for applications

– with ≤ 49 subscribers

– with cycle time of ≥ 1 ms

– in existing networks (e.g. with PMCtendo DD5).

– Connection to the servo amplifier PMCprotego D via the fieldbus junction box PMC-

protego D.CAN-CANbus Adapter (fieldbus junction box, can be ordered as an option)

}

PROFIBUS DP Slave

– Hardware switching via software command, from CANopen to PROFIBUS DP.

– Networking between the motion controller and a PROFIBUS Master.

– Suitable for data exchange with a third party controller.

}

Ethernet

–

Ethernet TCP/IP

– Communication between the programming device and the motion controller

– Suitable for configuration, programming, commissioning

–

Modbus TCP/IP

– Communications protocol based on Industrial Ethernet (TCP/IP over Ethernet).