10

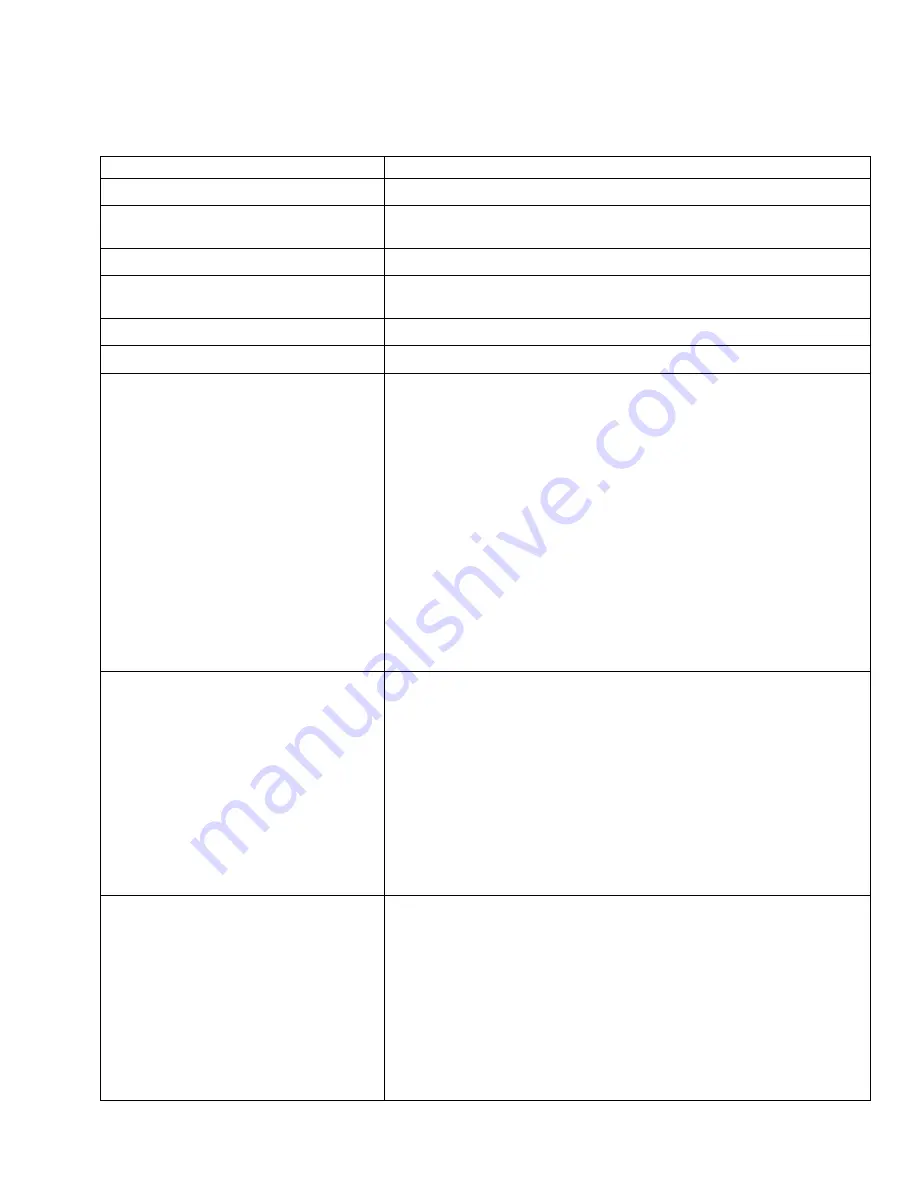

TROUBLESHOOTING

PROBLEM REMEDY

1. System bypass open.

Close bypass valve and open inlet/outlet valves

2. Excessive air flow.

Check rated output capacity of air compressor; a larger system

may be needed.

3. High inlet air temperature.

A larger system or after-cooler may be needed (consult factory)

4. Dirty heat exchanger.

Disconnect dryer inlet/outlet and flush with steam cleaner and

copper solvent.

5. Drain malfunction.

Clean or replace.

6. Not draining all moisture.

Adjust on/off times to drain – longer and/or more frequently.

7. Refrigerant compressor cycling

due to high refrigerant pressure or

overload

a. Overloaded unit.

b. Dirty atmosphere.

c. High ambient temperature.

d. Condenser fan motor failure.

e. Incorrect high-pressure

shutdown setting.

f. Bad compressor.

Reduce load or install larger system.

Clean condenser and install filter. Relocate unit or convert to

water-cooled unit.

Provide suitable ventilation or relocate unit. Consult factory.

Repair or replace.

Correct to: R-134a: 235 PSIG/16.2 BarG

R-22: 350 PSIG/2724.1 BarG

Replace compressor and liquid and suction line filters.

8. Refrigerant compressor cycling on

low pressure

a. Refrigerant low.

b. Incorrect low pressure control

setting.

c. Low-pressure control

malfunction.

Inspect for leaks, repair, evacuate and recharge. Consult factory.

Correct to:

R-134a: cut out 20 PSIG/1.38 BarG, cut in 30 PSIG/2.07 BarG

R-22: cut out 40 PSIG/2.16 BarG, cut in 60 PSIG/4.14 BarG

Units supplied with pump down:

R-22: cut out 25 PSIG/1.73 BarG, cut in 35 PSIG/2.42 BarG

Replace.

9. Refrigerant suction temperature

too low/freeze up.

a. Check fan cycle switch (if

supplied).

b. Ambient temperature too low.

Correct settings:

#1 Fan

R-134a: cut out 75 PSIG/5.2 BarG, cut in 125 PSIG/8.6 BarG

R-22 : cut out 150 PSIG/10.4 BarG, cut in 230 PSIG/15.9 BarG

#2 Fan

R-134a: cut out 110 PSIG/7.6 BarG, cut in 160 PSIG/11.4 BarG

R-22 : cut out 200 PSIG/13.8 BarG, cut in 275 PSIG/19 BarG

Relocate unit to a heated room/install low ambient package.

Consult factory.

Summary of Contents for ADR Series

Page 7: ...7 INSERT FLOW DIAGRAM ...