inlet and outlet valves, and close the bypass line valve. Allow the unit to run for one hour with airflow.

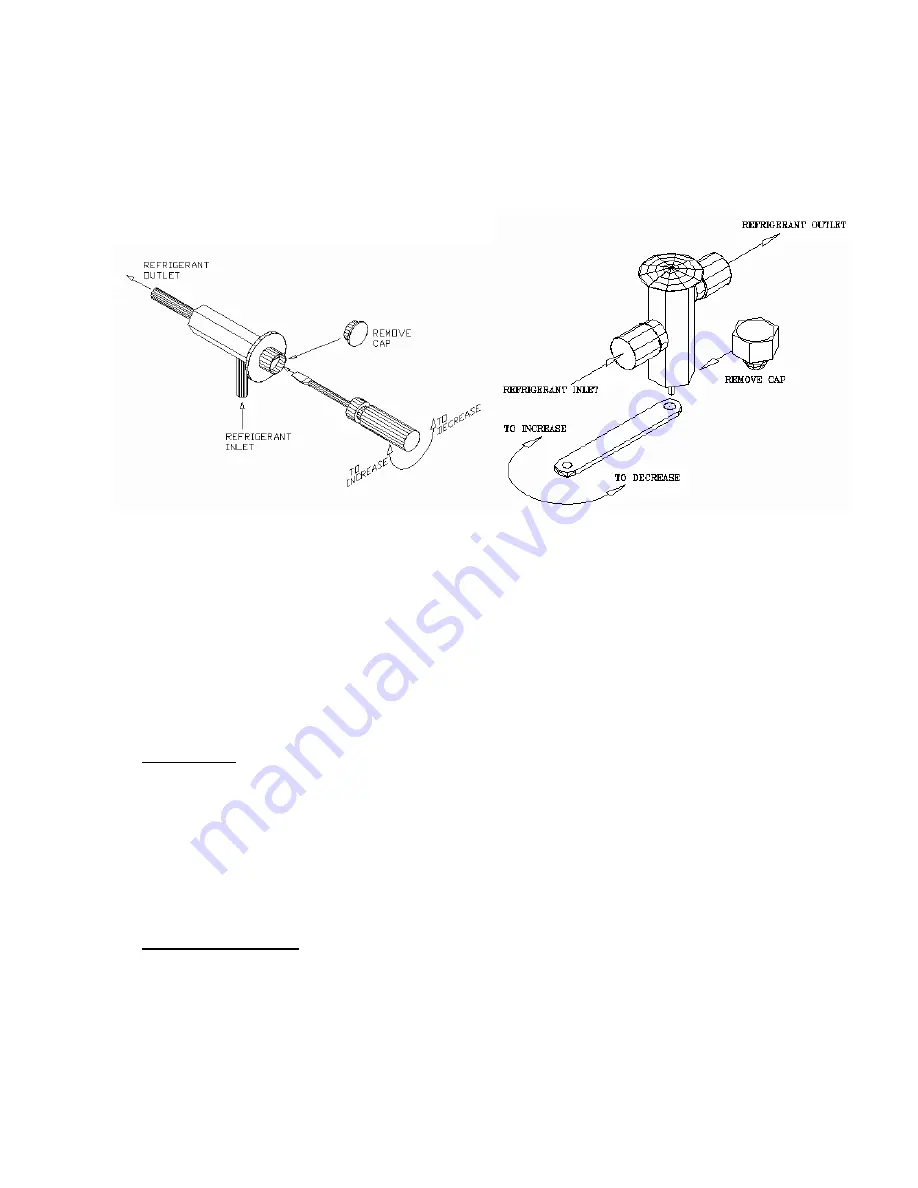

Adjustment to the hot gas bypass valve or expansion valve may be necessary at this time to obtain the

desired refrigeration suction temperature (this is not under warranty). See Figure 2.

Figure 2: Adjustment of Hot Gas Bypass and Expansion Valve.

Models R20 and larger are equipped with a timer operated drain to remove water from the moisture

separator. The drain open time is adjustable in seconds. The close time is adjustable in minutes. The

open time should be adjusted to exhaust water for approximately 80% of the open time and air for the

remainder of the time. The closed time shall be adjusted to prevent condensate carry-over or over

accumulation of condensate.

Caution: Starting unit immediately without following the above instructions may cause damage.

How a Typical Refrigerant Dryer Works

Air Circuit:

The warm moist air enters the air-air heat exchanger, where it is pre-cooled with

outgoing cool air (R30A/W & larger). Pre-cooling allows use of a smaller refrigeration unit and lowers

the cost of drying. The air is further cooled to the 35

o

F/2

o

C range in the air-refrigerant heat exchanger.

Cooling the compressed air causes condensation of moisture which is separated by a highly efficient

moisture separator. An automatic drain periodically drains the condensate. Cold dry air from the

separator flows through the air-air heat exchanger where it is reheated by the incoming warm air.

Reheating increases the volume of air, pre-vents moisture condensation on the air lines, and lowers the

relative air humidity. The clean dry air is then available for use.

Refrigerant Circuit:

The refrigerant compressor compresses cold refrigerant vapor into warm or

hot high-pressure gaseous refrigerant. Because of compression, the refrigerant temperature is high

enough to transfer heat to the atmosphere (air-cooled units) or water (water-cooled units). Hot or warm

refrigerant flows into the condenser where it is cooled and condensed into liquid. Liquid refrigerant the

flows to the receiver (R75 or ADR40 and larger). From the receiver, the liquid refrigerant flows through

a filter dryer to an expansion valve. The function of the receiver is to assure availability of liquid

refrigerant for expansion. The expansion valve lowers the refrigerant pressure and temperature. In a

typical air dryer system of 35

o

F/2

o

C PDP, the refrigerant temperature is lowered to the 30 to 34

o

F (-1 to

5

Summary of Contents for ADR Series

Page 7: ...7 INSERT FLOW DIAGRAM ...