Machine Care

11

Maintenance Schedule

Caution!

Only qualified personnel authorized by Amano Pioneer Eclipse should perform each maintenance and repair

operation not described here as ordinary maintenance.

After Each Use

Clean the recovery tank.

Clean the filter of the vacuum motors.

Check the filter of the clean water tank.

Check the condition of the suction pipes and of the squeegee; clean if necessary.

Weekly

Check the condition of brushes.

Check the condition of the rubber squeegee blades.

Monthly

Check the condition of the scrubbing solution delivery valve.

Every six months, check the condition of the brushes.

Squeegee Blade Replacement

The squeegee blades should be replaced when the contact edge becomes worn, since the perfection of the

edge is essential for perfect drying. To replace the blades, the squeegee should be removed from the

machine. With the squeegee support in the UP position, remove the suction pipe from the squeegee and

partially unscrew the screws. Remove the squeegee from the machine. Remove the screws on the front part

and on the rear part of the squeegee, the steel straps, and the worn rubber blades. Perform the inverse

procedure to change the blades, and reassemble the squeegee. Replace the squeegee on the machine and

adjust.

Vacuum Motor Maintenance

The vacuum motors must be checked and cleaned. The brushes should be checked every six months and

replaced, if necessary.

After removing the key from the dashboard, remove the vacuum motor by loosening the knobs and removing

the connection plug. Release the sponge filter under the motors so that it can be cleaned and replaced.

Check the suction fan from the hole located in the front part of the vacuum motor. By a visual check, the fan

should appear undamaged and well cleaned. To check the brushes, first remove the plastic cap, then

unscrew the screws and remove the two plastic brush supports. Once checked and replaced (if necessary),

the brushes can be easily remounted by reassembling all elements.

Diagnostic Messages

The machine is equipped with a system of flashing light bars to alert the operator of system faults or other

problems. Use the key below to diagnose system faults.

10 bars: High Battery Voltage

9 bars: Solenoid Brake Fault

8 bars: Control System Fault

7 bars: Throttle Fault

6 bars: Inhibit Active

5 bars: Vacuum Motor Fault

4 bars: Freewheel Active

3 bars: Brush Motor Fault

2 bars: Traction Motor Fault

1 bar: Low Battery Voltage

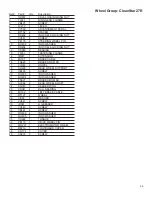

Summary of Contents for CS2700R

Page 15: ...Wiring Schematic CleanStar 27R 14 ...

Page 16: ...15 ...

Page 17: ...Tanks Cover Group CleanStar 27R 16 ...

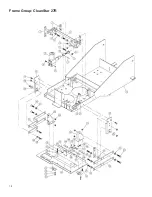

Page 19: ...Frame Group CleanStar 27R 18 ...

Page 21: ...Brush Housing Group CleanStar 27R 20 ...

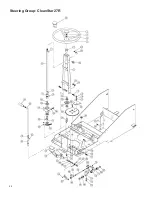

Page 23: ...Steering Group CleanStar 27R 22 ...

Page 25: ...Wheel Group CleanStar 27 R 24 ...

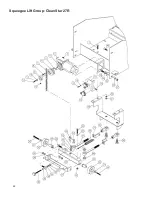

Page 27: ...Squeegee Lift Group CleanStar 27R 26 ...

Page 29: ...Vacuum Group CleanStar 27R 28 ...

Page 31: ...Solution Flow Group CleanStar 27R 30 ...

Page 33: ...Squeegee Assembly Group CleanStar 27R 32 ...

Page 35: ......

Page 37: ......