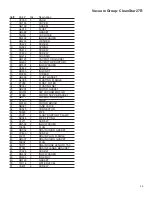

Summary of Contents for CS2700R

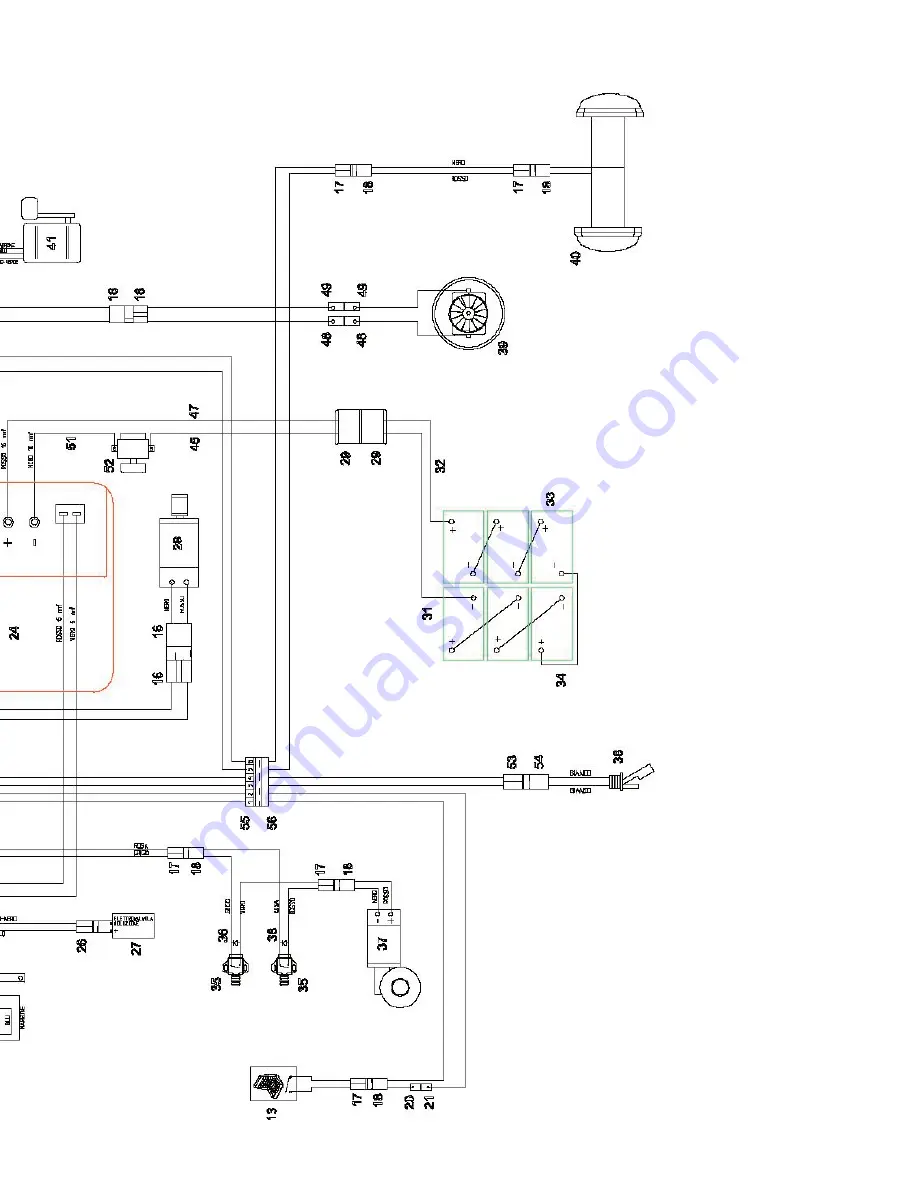

Page 15: ...Wiring Schematic CleanStar 27R 14 ...

Page 16: ...15 ...

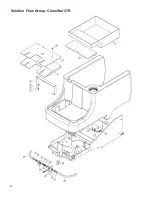

Page 17: ...Tanks Cover Group CleanStar 27R 16 ...

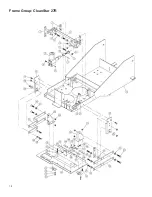

Page 19: ...Frame Group CleanStar 27R 18 ...

Page 21: ...Brush Housing Group CleanStar 27R 20 ...

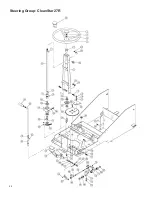

Page 23: ...Steering Group CleanStar 27R 22 ...

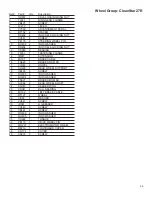

Page 25: ...Wheel Group CleanStar 27 R 24 ...

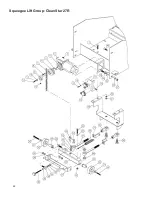

Page 27: ...Squeegee Lift Group CleanStar 27R 26 ...

Page 29: ...Vacuum Group CleanStar 27R 28 ...

Page 31: ...Solution Flow Group CleanStar 27R 30 ...

Page 33: ...Squeegee Assembly Group CleanStar 27R 32 ...

Page 35: ......

Page 37: ......