Summary of Contents for CDX-MG6056ZH

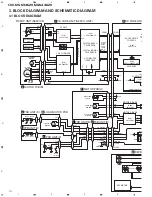

Page 5: ...4 CDX MG6346ZH MG6446ZH 2 2 EXTERIOR ...

Page 7: ...6 CDX MG6346ZH MG6446ZH 2 3 CD MECHANISM ...

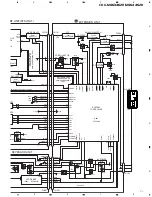

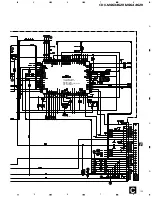

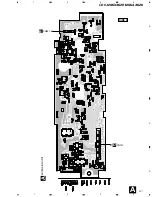

Page 14: ...13 CDX MG6346ZH MG6446ZH 5 6 7 8 5 6 7 8 D C B A A A b A EXTENSION UNIT ...

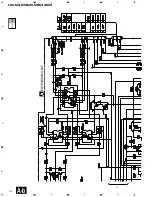

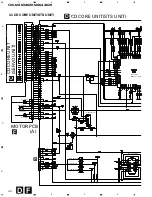

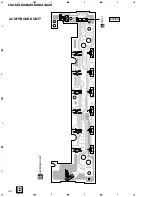

Page 15: ...14 CDX MG6346ZH MG6446ZH 1 2 3 4 1 2 3 4 D C B A 1 A a A b D CD CORE UNIT STS UNIT A a ...

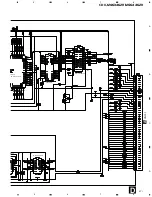

Page 16: ...15 CDX MG6346ZH MG6446ZH 5 6 7 8 5 6 7 8 D C B A A a A b B 2 B KEYBOARD UNIT A a ...

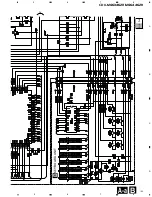

Page 17: ...16 CDX MG6346ZH MG6446ZH 1 2 3 4 1 2 3 4 D C B A A a A b 1 A EXTENSION UNIT A b ...

Page 18: ...17 CDX MG6346ZH MG6446ZH 5 6 7 8 5 6 7 8 D C B A A a A b 2 A b ...

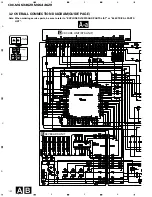

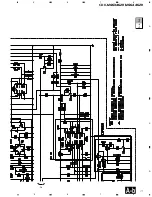

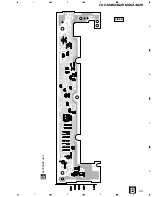

Page 28: ...27 CDX MG6346ZH MG6446ZH 1 2 3 4 1 2 3 4 D C B A CN701 CN901 EXTENSION UNIT SIDE B A A B D ...

Page 30: ...29 CDX MG6346ZH MG6446ZH 1 2 3 4 1 2 3 4 D C B A SIDE B KEYBOARD UNIT B B ...

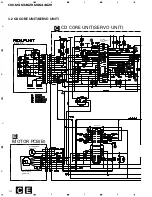

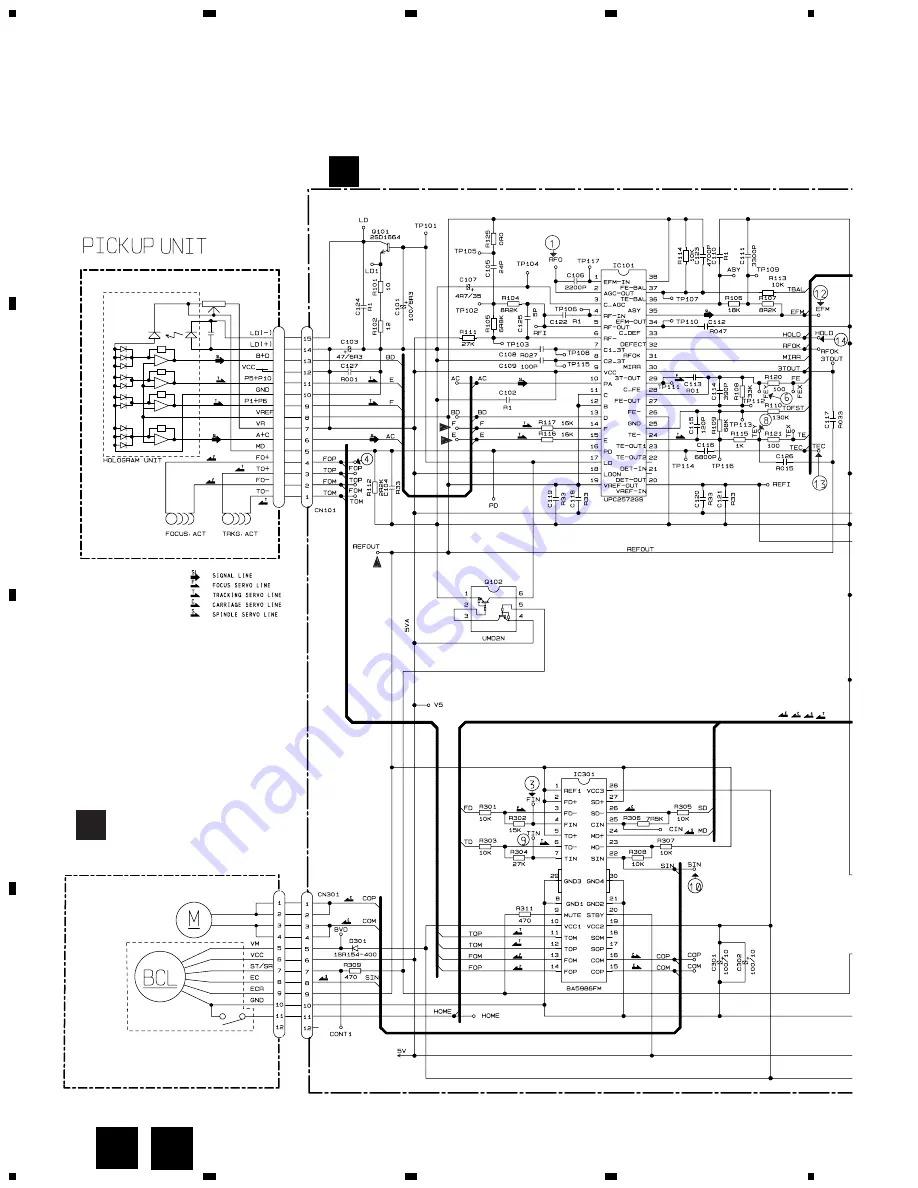

Page 32: ...31 CDX MG6346ZH MG6446ZH 1 2 3 4 1 2 3 4 D C B A CD CORE UNIT SERVO UNIT SIDE B C C ...

Page 34: ...33 CDX MG6346ZH MG6446ZH 1 2 3 4 1 2 3 4 D C B A CD CORE UNIT STS UNIT SIDE B D D ...

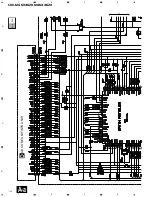

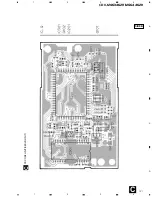

Page 36: ...M M4 CARRIAGE 1 12 D CN301 35 CDX MG6346ZH MG6446ZH 5 6 7 8 5 6 7 8 D C B A E C ...

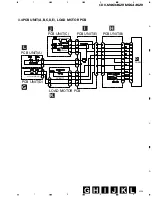

Page 38: ...1 41 G CN801 37 CDX MG6346ZH MG6446ZH 1 2 3 4 1 2 3 4 D C B A MOTOR PCB A F SIDE B F D ...