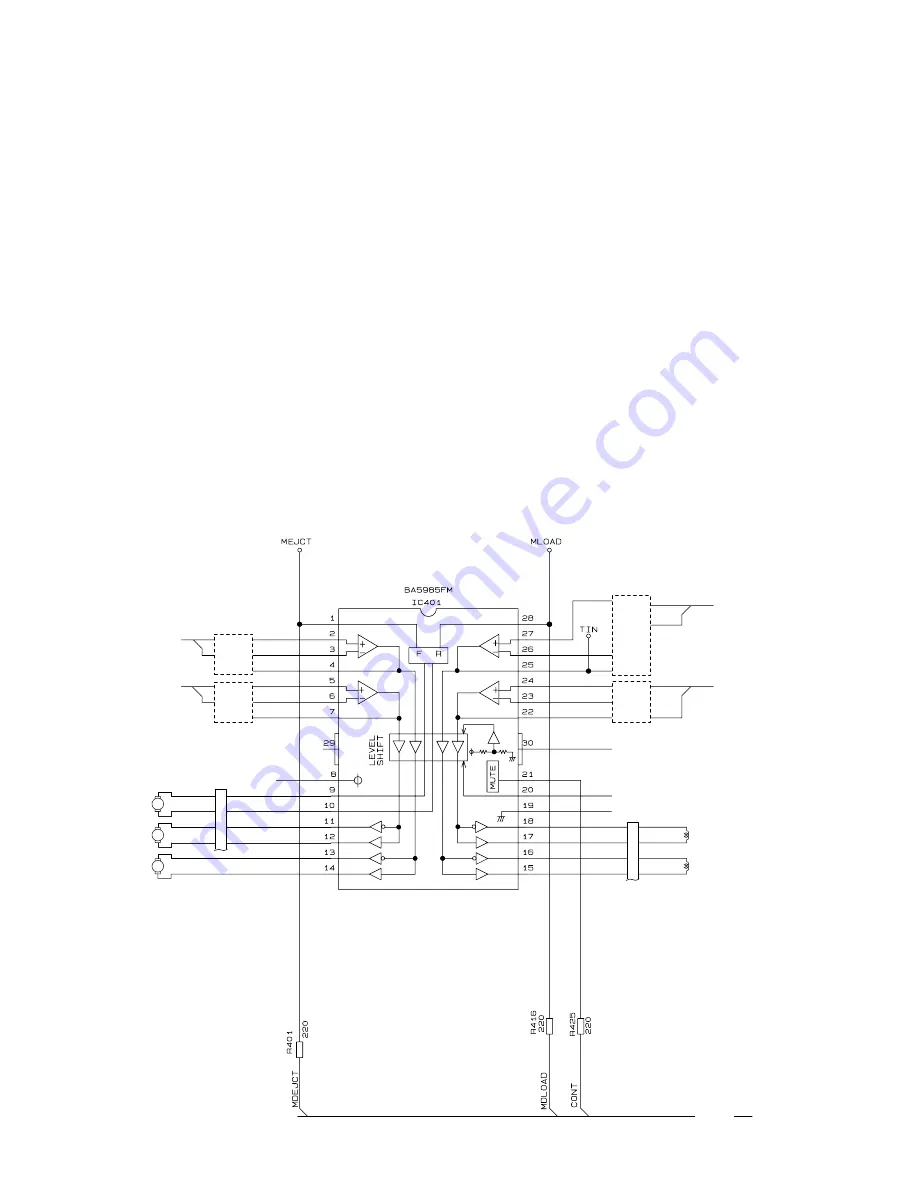

1.3 POWER SUPPLY AND DRIVER BLOCK (BA5985FM: IC401)

1) Power supply

Switched system power supplies MDVD and PVD (8.3V) from the mother board and backup system power supply VDD

(5V) are used for this system (see the power supply system diagram).

3.3V for driving MD/LSI system and LD is generated from MDVD. In order to drive large current, only PVD (3.3V) is

used as the driver power.

Pro-test is prepared to detect voltage error in MDVD.

As soon as overvoltage beyond 9.9V or undervoltage below 3.5V is detected, MD microcomputer turns off the start

control signal (VDON) from VD to stop supply of VD from the mother PCB.

In this case, ERR A0 indicating a power supply system error is displayed on the product.

2) Driver block

It is a linear driver used for driving 5 channels consisted of 1 channel on Load/EJ system and 4 channels on

actuator/SPDL/CRG system.

Forward/reverse drive (approximately 7.5V) of the Load/EJ system is implemented by the control signals (MLOAD AND

MEJCT) from the MD microcomputer.

4-channel system conducts binary PWM signal to the differential L.P.F, then supplies it driver.

You can monitor respective signals as analog signals (FIN, TIN, SIN and CIN).

10

CX-683

M

M

M

MEJCT

C+

C–

CIN

S+

S–

SIN

GND

LOP

LOM

SOM

SOP

COM

COP

MLOAD

T+

T–

TIN

F+

F–

FIN

GND

PVC

CONT

GND

FOM

FOP

TOM

TOP

CRG

SYSTEM

RC

LADDER

RC

LADDER

FOCUS

SYSTEM

RC

LADDER

SPDL

SYSTEM

RC

LADDER

PVD

LOAD/ET

Motor

SPDL

Motor

CRG

Motor

FOCUS

actuator

TRKG

actuator

CN401

LO+

LO–

SO+

SO–

CN101

F–

F+

T–

T+

SFDR

SRDR

SPRD

SPFD

< IC201 >

< IC201 >

< IC301 >

MD microcomputer

TRKG SYSTEM

TRDR

TFDR

< IC201 >

FFDR

FRDR

< IC201 >