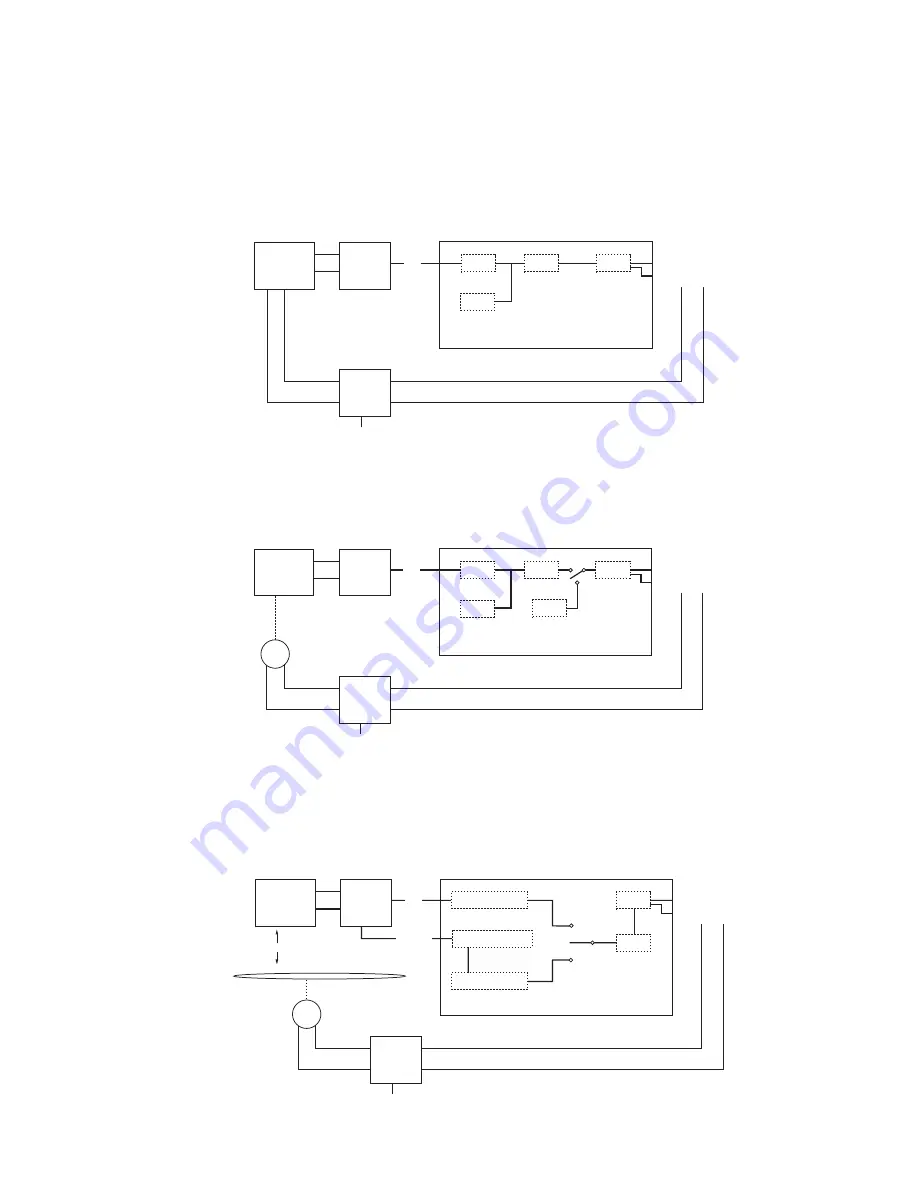

Tracking Servo System

The system causes the microcomputer to issue the tracking close instruction to the IC, then switches the spindle

control from the ofst drive to the CLV control.

The close operation completes when the Disc address has been read after the spindle LOCK signal went high

(Can be monitored on the mnt0 terminal when the mnt selector is set to 00).

Carriage Servo System

The carriage operation is turned on at the moment when the tracking close instruction is issued. The system drives

the carriage according to DC_ofst volume specified on the actuator.

7

CX-683

A/D

TE

TIN (For monitoring control signal)

TOP

TOM

E

F

RF

amplifier

Driver

Pick up

IC201

IC101

IC401

OFST

EQ

PWM

TFDR 86pin

TRDR 85pin

A/D

SE

CIN (For monitoring control signal)

COP

COM

E

F

RF

amplifier

Driver

Carriage Motor

Pick up

IC201

IC101

IC401

OFST

EQ

Move

PWM

SFDR 92pin

SRDR 91pin

M

Timing Control

Timing Control

RF

ADFG

SIN (For monitoring control signal)

SOP

SOM

RF

amplifier

Driver

Spindle Motor

Pick up

IC201

IC101

IC401

FM Demodulation

EQ

pre_disc

rec_disc

PWM

SFDR 92pin

SRDR 91pin

M

Spindle Servo

As for pre_disc, the spindle servo implements CLV control utilizing EFM signal.

As for rec_disc, the servo implements CLV control utilizing ADIP signal generated for respective disc groups.

The locking status of the spindle servo can be monitored on the MNT3 terminal by setting the monitor selector to 00.