Leakage Current Cold Check

With the AC plug removed from an AC power source, place a

jumper across the two plug prongs. Turn the AC power switch on.

Using an insulation tester (DC 500V), connect one lead to the

jumpered AC plug and touch the other lead to each exposed metal

part (input/output terminals, screwheads, metal overlays, control

shafts, etc.), particularly any exposed metal part having a return

path to the chassis. Exposed metal parts having a return path to

the chassis should have a minimum resistor reading of 0.3M

Ω

and a maximum resistor reading of 5M

Ω

. Any resistor value

below or above this range indicates an abnormality which

requires corrective action. Exposed metal parts not having a

return path to the chassis will indicate an open circuit.

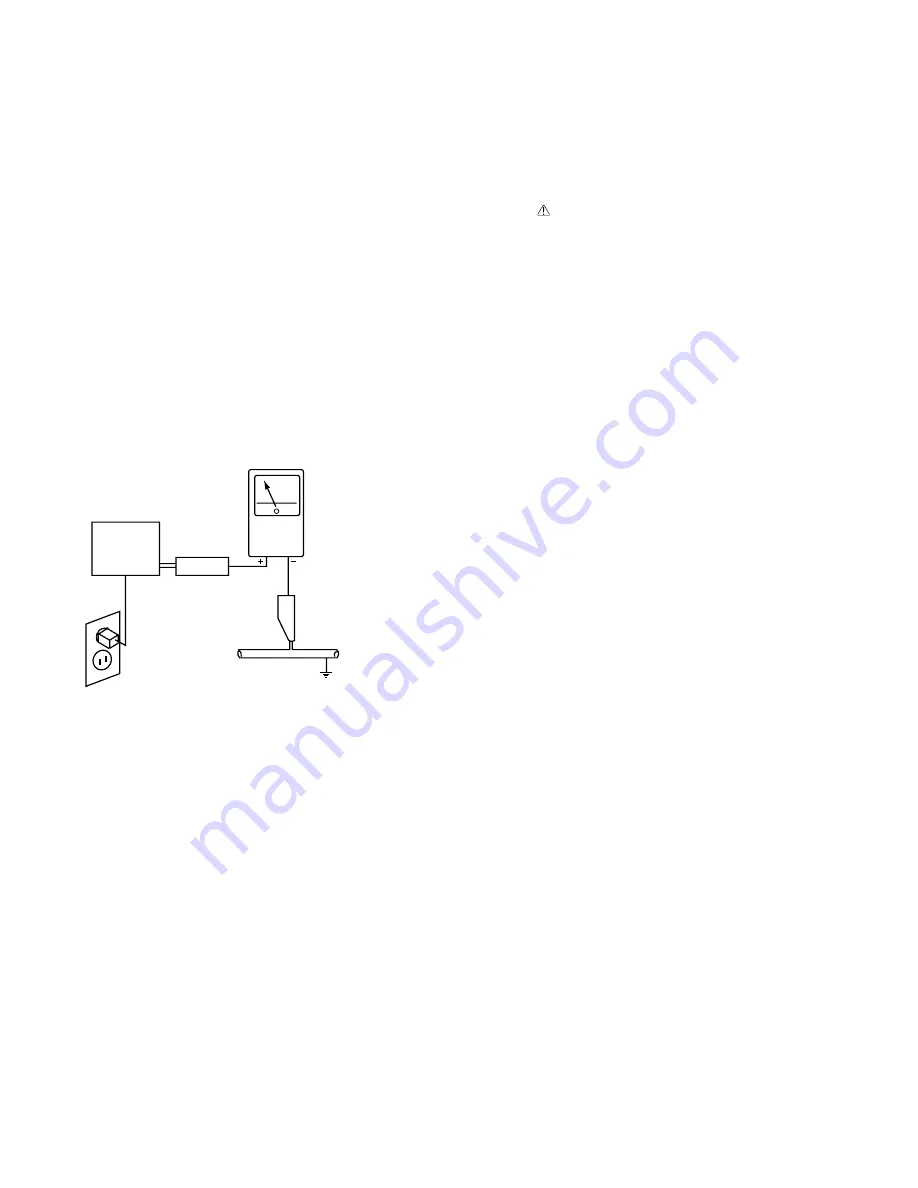

Leakage Current Hot Check

Plug the AC line cord directly into an AC power source (do not

use an isolation transformer for this check).

Turn the AC power switch on.

U s i n g a " L e a k a g e C u r r e n t Te s t e r ( S i m p s o n M o d e l 2 2 9

equivalent)", measure for current from all exposed metal parts of

the cabinet (input/output terminals, screwheads, metal overlays,

control shaft, etc.), particularly any exposed metal part having a

return path to the chassis, to a known earth ground (water pipe,

conduit, etc.). Any current measured must not exceed 0.5mA.

A N Y M E A S U R E M E N T S N O T W I T H I N T H E L I M I T S

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE SET TO THE CUSTOMER.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in PIONEER set have

special safety related characteristics. These are often not evident

from visual inspection nor the protection afforded by them

necessarily can be obtained by using replacement components

rated for higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in this

Service Manual.

Electrical components having such features are identified by

marking with a on the schematics and on the parts list in this

Service Manual.

The use of a substitute replacement component which dose not

h a v e t h e s a m e s a f e t y c h a r a c t e r i s t i c s a s t h e P I O N E E R

recommended replacement one, shown in the parts list in this

Service Manual, may create shock, fire or other hazards.

Product Safety is continuously under review and new instructions

are issued from time to time. For the latest information, always

consult the current PIONEER Service Manual. A subscription to,

or additional copies of, PIONEER Service Manual may be

obtained at a nominal charge from PIONEER.

Leakage

current

tester

Reading should

not be above

0.5mA

Device

under

test

Test all

exposed metal

surfaces

Also test with

plug reversed

(Using AC adapter

plug as required)

Earth

ground

AC Leakage Test

2-2

Summary of Contents for Elite PureVision PRO 1410HD

Page 5: ...2 3 ...

Page 6: ...2 4 ...

Page 8: ...SPECIFICATIONS PDP 614MX 3 1 ...

Page 9: ... PRO 1410HD 3 2 ...

Page 10: ...TABLE OF SIGNAL SUPPORTED PDP 614MX 4 1 ...

Page 11: ...4 2 ...

Page 12: ...4 3 PRO 1410HD ...

Page 13: ...4 4 ...

Page 14: ...PANEL FACILITIES 5 1 PDP 614MX ...

Page 15: ...5 2 ...

Page 16: ...5 3 PRO 1410HD ...

Page 17: ...5 4 ...

Page 32: ...7 11 ...

Page 44: ...All white signal All white signal 8 12 ...

Page 50: ... Fig 1 CCD PWB Pattern Diagram A B D E 3 3V 6V C 8 18 ...

Page 51: ...8 19 Check point MAIN PWB ...

Page 52: ...8 20 232C PWB ...

Page 53: ...8 21 CLT PWB ...

Page 54: ...8 22 PWR PWB ...

Page 55: ...8 23 LED PWB ...

Page 56: ...8 24 SENB PWB ...

Page 57: ...8 25 SENC PWB ...

Page 58: ...8 26 SEND PWB ...

Page 59: ...AUDIO PWB 8 27 ...

Page 60: ...8 28 CCD PWB PX A only ...