23

2) Unpacking procedures

1

Remove the packing bands.

2

Slowly lift and remove the upper carton.

3

Lift and remove the carton cover.

4

Remove the pads.

5

Remove the accessory and power cord cases.

6

Remove the unit (requires two or more people).

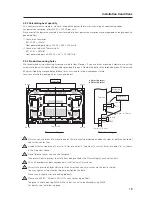

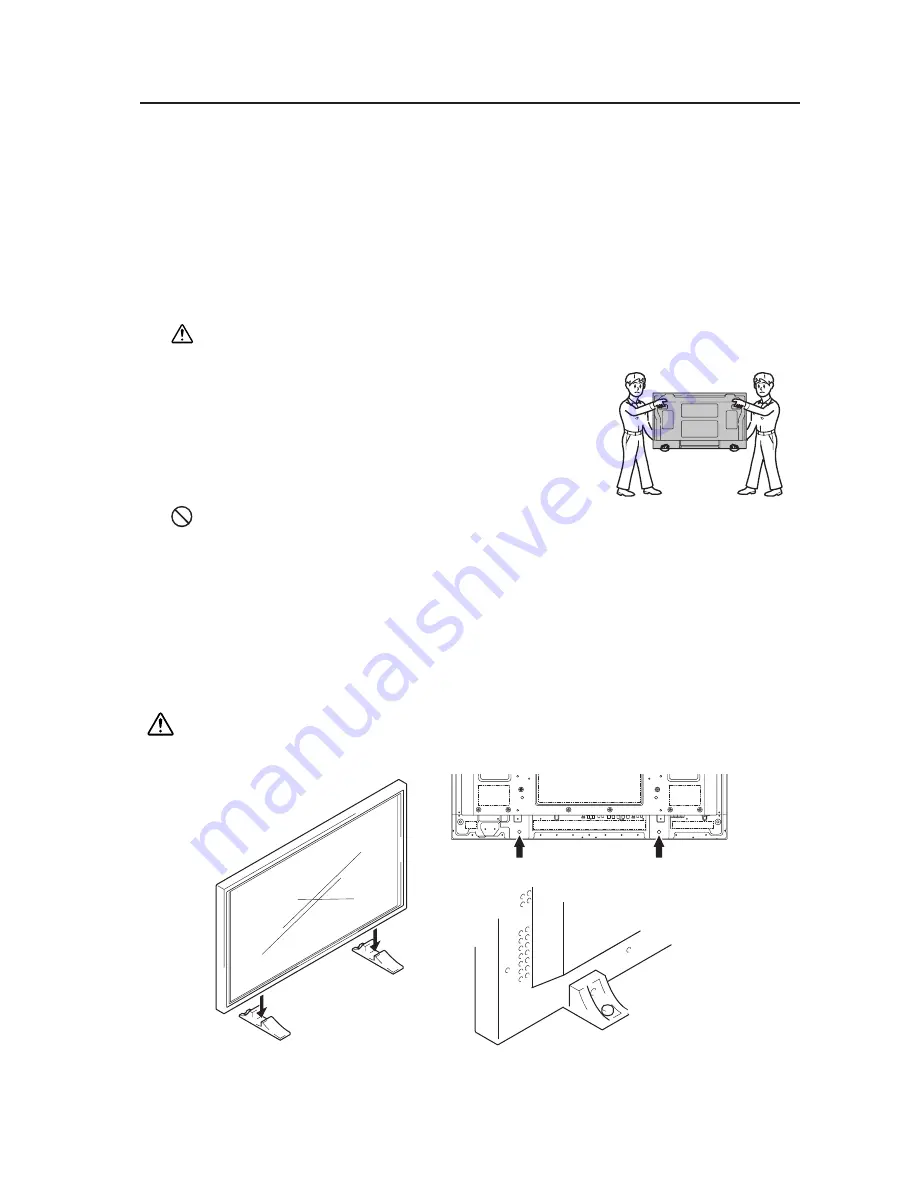

3) Transportation of the unpacked unit.

If it needs to be moved, the unit should be lifted by two or more people.

Caution

• Never move the unit by dragging it along the floor.

• Move the unit slowly, taking care to prevent scraping or striking the delicate

front protective panel.

• In order to prevent adhesion of dust, remove the protective film only after

all work and preparations for the installation site, including clean-up following

unpacking, are complete.

• When moving the display, it should always be carried by two people holding

the rear handles in the manner shown.

No!

Never attempt to move the Plasma Display by holding only one of the handles.

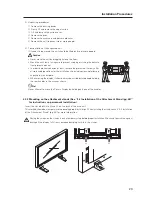

3.3.3 Mounting on the attachment stands (See

" 4.3 Installation of the Attachment Stand (pg. 48)"

for instructions on permanent installation.)

Insert the stand bolts into

A

and

A

' on the back of the main unit.

This method should be a temporary setup pending proper installation. When installing the stand, consult “4.3 Installation

of the Attachment Stand” (pg. 48) for more information.

Placing the screen on the stands is only a temporary step before proper installation. We cannot guarantee against

damage if the display falls from someone bumping it while in the stands.

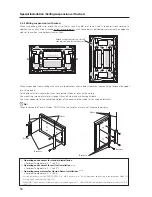

Installation Procedures

A

A

'