117

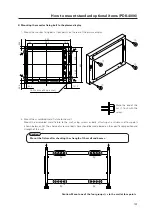

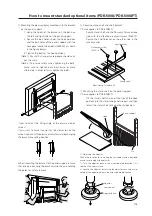

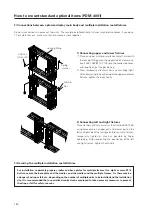

How to mount standard optional items (PDM-4001)

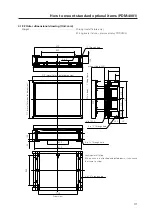

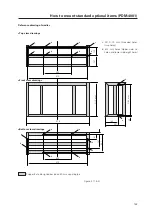

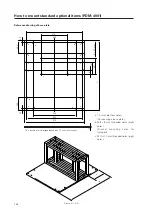

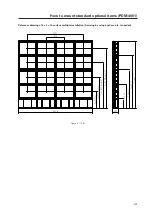

4.12.2 Outer dimensional drawing [Unit: mm]

Weight ........................................................................ 20.6 kg (metal fixture only)

51.4 kg (metal f plasma display PDP-V402)

Front view

12 Through hole

919 (metal fixture outer dimension)

717 (metal fixture outer dimension)

(when sliding: 229)

Sliding frame

Main body

Locking metal fitting

(When a chain is attached and pulled down, it can cause

the frame to slide.)

6- ø 12 Through hole

8- ø 12 Through hole

711.9

2- ø 12 Through hole

6- ø 12 3.5

870

400

200

10

870

600

6- ø 6

120

30

158.5

210

210

877

PDP

30

120

560

Summary of Contents for PDK-5008

Page 5: ...5 Features ...

Page 11: ...11 Remote control ...

Page 21: ...21 Installation procedure ...

Page 57: ...57 Special installation Installation under the floor ...

Page 85: ...85 How to mount standard optional items PDK 4001 ...

Page 91: ...91 How to mount standard optional items PDK 4002 ...

Page 97: ...97 How to mount standard optional items PDK 4004 ...

Page 115: ...115 How to mount standard optional items PDK 5008 PDK 5008FT ...

Page 153: ...153 How to mount standard optional items Precautions for installing the optional speaker ...

Page 161: ...161 Before making adjustments ...