70

PDR-509

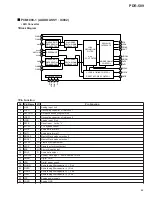

7.3 EXPLANATION

7.3.1 ERROR CODE

Laser Hour Meter Indication and Error Code Display for Service

The PDR-509 can display the total turn-on time of the laser diode

and error codes for service.

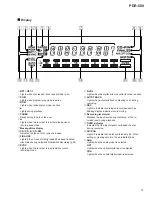

When the STOP key is held down for about 5 seconds in stop

state in Normal mode, an FL display as shown below is obtained.

Left 4 FL digits

: Total turn-on time of the laser diode

Right 2 FL digits : Error code for service

The total turn-on time of the laser diode is displayed in the range

of 0 to 5100.

The error code for service is displayed as a number (ERROR

NUMBER), which follows a message "CHECK DISC" or

"CHECK." For details, see the table below.

To initialize the total turn-on time of the laser diode, hold the

STOP key down for about 5 seconds in stop state with the INPUT

selector set to analog in Test mode.

The message "CLEAR" is displayed, and the total time is cleared.

Display

Error code table for service

Laser Hour Meter

indicationsplay

Error code Number

∗∗∗∗ ∗∗

Code

Symptom

Contents of Error

Possible Cause

Checkpoints

H0

No operation even when

power is supplied.

Communication between mechanism

controller and mode controller is not

achieved.

• Improper soldering

• Pattern short

IC301 (PE5109A)

IC351 (PDJ014A)

H1

(CHECK display)

Defective mechanism controller

terminals

• Short-circuiting of parts

• Improper power supply

IC371

(HD74HC573FP)

H2

Pre-recording process does

not complete, and the tray

does not open.

(CHECK display)

Improper input voltage at the

mechanism-control terminals

(pins 22, 23, 24)

IC201 (PA9007A)

H5

Pre-recording process

disabled (CHECK display)

Improper IC303 data writing

• Defect in IC303

IC303 (PYY1196)

L

∗

The unit stops during the

tray open/close operation.

(CHECK display)

Improper loading

• Defective tray position sensor

• Defective loading motor

• Improper soldering

• Pattern short

• Improper power supply

IC451 (M56788FP)

E

∗

The unit stops when PLAY

or REC/PAUSE starts.

(CHECK display)

Defective slider

• The pickup cannot be returned to the

specified position.

• Disconnected flexible cable

• Defective drive circuit

• Abnormal power supply

• Abnormal TOC position switch

• Improper soldering

S601 (PSG1013)

IC451 (M56788FP)

IC401 (CXD2585Q)

P

∗

The unit does not read the

inserted disc, and stops.

(CHECK DISC display)

Defect in spindle

• Disc upside-down.

• Dirty or cracked disc

• Abnormal disc rotation

• No signal obtained from the disc

• Defective spindle motor

• Defective spindle drive circuit

• Abnormal FG signals

• Defective WBL circuit

• Defective decoder circuit

• Unable to read ATIP or subcode

• High error rate

PC651

(NJL5803K-F1)

IC451 (M56788FP)

IC401 (CXD2585Q)

∗

1

∗

1

∗

1 : SERVO MECHANISM Assy

Summary of Contents for PDR-509

Page 19: ...PDR 509 19 A B C D 5 6 7 8 5 6 7 8 CDR SERVO AMP MULTI PLEXER A1 5 A4 5 A3 5 A1 5 1 3 5 A ...

Page 43: ...PDR 509 43 A B C D 5 6 7 8 5 6 7 8 PNP1466 A Q701 Q704 PNP1466 A CN51 J SIDE A SIDE B I ...

Page 45: ...PDR 509 45 A B C D 1 2 3 4 1 2 3 4 J K PNP1466 A POWER SUPPLY ASSY J REG ASSY K SIDE B ...

Page 68: ...68 PDR 509 FL TUBE 7 2 2 DISPLAY PEL1099 FUNCTION ASSY V701 Anode Grid Assignment 1 35 ...

Page 69: ...69 PDR 509 Pin Assignment ...

Page 73: ...73 PDR 509 MONITOR DIGITAL REC LEVEL ANALOG REC LEVEL INPUT SELECTOR TIME REPEAT ...