12

© 2006 Pioneer Supply International

12

© 2006 Pioneer Supply International

Site Considerations

WARNING:

DO NOT allow unsupervised children or visitors in shop at any time.

Floor Load

The PNR 14-150 has a shipping weight of 560 lbs (254Kg), net weight of 500 lbs (226.8Kg), and a

base footprint of 32" x48".

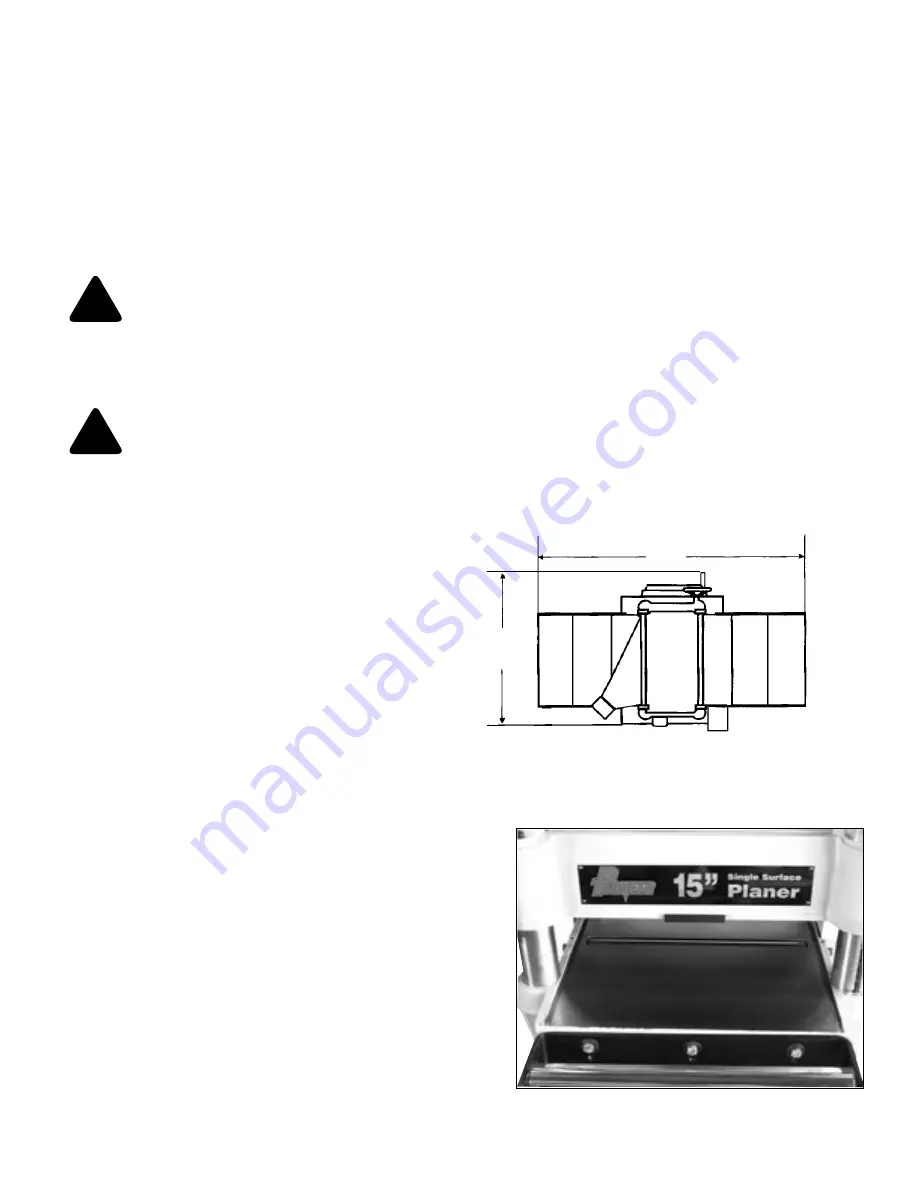

Working Space

In order to have a safe working environment, there

should be enough space around the machine to

walk around the machine and enough room to plane

material both at the infeed and outfeed sides without

bumping into other people, machines and obstruc-

tions. See Figure 4.

Moving & Placing Planer

The cabinet stand on the PNR 14-150 is equipped with lifting bars (Refer to page 9) to lift and place the plan-

er. When lifting the planer with a forklift, place shop rags or cardboard between the forks and cabinet base so

you do not scratch the paint.

Extension Wings

You will need:

Two Table Extension Wings, 6 x Hex Bolts, 6 x

Lock Washers, 6 x Flat Washers. 4 x Set Screws.

To attach the table extension wings:

1 Install set screws in the holes in the side of the

wings (see Figure 5).

2 Attach the table extension wings to the planer table

with the hex bolts, lock washers, and flat washers,

as shown in Figure 6, but do not fully tighten the

!

Figure 4

Figure 5

Cleaning

The unpainted surfaces are coated with a waxy oil to protect them from corrosion during shipment. Remove

this protective coating with a solvent cleaner or citrus-based degreaser to clean thoroughly, some parts may

need to be removed. For optimum performance from your machine, make sure you clean all moving parts

or sliding contact surfaces that are coated. Avoid chlorine-based solvents, such as acetone or brake parts

cleaner, as they may damage painted surfaces should they come in contact. Always follow the manufacturer’s

instructions when using any type of cleaning product.

These items are coated and must be cleaned:

Cutter head, Table, Feed Rollers, and Extension Wings.

WARNING:

Gasoline and petroleum products have low flash points and could cause an explo-

sion or fire if used to clean machinery. DO NOT use gasoline or petroleum products to clean the

machinery. Many of the solvents commonly used to clean machinery can be toxic when inhaled or

ingested. Lack of ventilation while using these solvents could cause serious personal health risks

or fire. Take precautions from this hazard by only using cleaning solvents in a well ventilated area.

!

Summary of Contents for PNR 14-150

Page 4: ...4 2006 Pioneer Supply International 4 2006 Pioneer Supply International ...

Page 5: ... 2006 Pioneer Supply International 5 ...

Page 6: ...6 2006 Pioneer Supply International 6 2006 Pioneer Supply International ...

Page 28: ...28 2006 Pioneer Supply International 28 2006 Pioneer Supply International ...

Page 29: ... 2006 Pioneer Supply International 29 ...

Page 30: ...30 2006 Pioneer Supply International 30 2006 Pioneer Supply International ...