c.

On PA-28R-201, check the position of the pinion to be sure the unit will mesh properly with the

flywheel ring rear. See specifications of unit for correct dimensions. Refer to paragraph 11-63.

11-61. BENCH TESTS.

a.

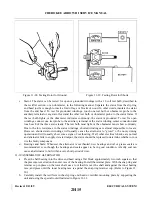

After the starting motor is reassembled, it should be tested to see that the no-load current at a certain

voltage is within specifications as given in paragraph 11-62. To make this test, connect as shown in

Figure 11-42. If current is too high, check the bearing alignment and end play to make sure there is no

binding or interference. Two or three sharp raps on the frame with a rawhide hammer will often help to

align the bearings and free the armature.

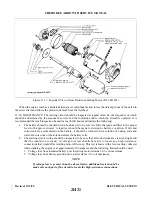

b. If no difficulty is indicated in the above test, a stall torque test may be made to see if the starting motor

is producing its rated cranking power. Make test connections as shown in Figure 11-43.

c.

If torque and current are not within specifications, check the seating of the brushes and internal

connections for high resistance. If these checks are made and found to be in good order, replace frame

and field assembly and retest starter.

11-62. STARTING MOTOR CONTROL CIRCUIT.

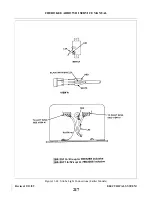

a.

Inspect the control circuit wiring between the battery, solenoid and manual starting switches for

breaks, poor connections and faulty insulation. Tighten all connections and make sure solenoid is

firmly mounted and makes a good ground connection.

b. Check the voltage loss across the switch contacts during normal starting. If loss is in excess of 0.2

volts per 100 amperes, the solenoid should be replaced.

c.

If solenoid fails to operate when the manual starting switch is turned on or if it fails to release when

the manual starting switch is released, it should be removed and tested to specifications. If either

opening or closing voltages are not to specifications, replace the solenoid.

11-63. STA RTING MOTOR SERVICE TEST SPECIFICATIONS. Prestolite specifications for standard

equipment 12-volt starting motors installed on both model aircraft are as shown in Table XI-III.

11-64. BATTERY.

11-65. SERVICING BATTERY. Access to the battery is through the aft side of the baggage compartment. It is

enclosed in a thermoplastic box with a vent system and a drain. The vents allow fresh air to enter the box and

draw off fumes that may accumulate due to the charging process of the battery. The drain is clamped off and

should be opened occasionally to drain any accumulation of liquid or during cleaning of the box. The battery

should be checked for fluid level but must not be filled above the baffle plates. A hydrometer check should be

performed to determine the percent of charge in the battery. All connections must be clean and tight.

11-66. REMOVAL OF BATTERY.

a.

Remove the access panel to the aft section of the fuselage.

b. Remove battery box cover.

c.

Disconnect the battery cables.

NOTE

Always remove the ground cable first and install last to prevent accidental

short circuiting or arching.

d. Lift the battery from the box.

Revised: 2/13/89

2I2

CHEROKEE ARROW III SERVICE MANUAL

ELECTRICAL SYSTEM

Summary of Contents for ARROW III

Page 4: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A4...

Page 12: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A12...

Page 94: ...Figure 4 2 Wing Installation Revised 2 13 89 1D22 CHEROKEE ARROW III SERVICE MANUAL STRUCTURES...

Page 171: ...lH3 INTENTIONALLY LEFT BLANK...

Page 172: ...lH4 INTENTIONALLY LEFT BLANK...

Page 286: ...THIS PAGE INTENTIONALLY LEFT BLANK Revised 2 13 89 2A8...

Page 528: ...INTENTIONALLY LEFT BLANK 2K10 THRU 2L24 2K10...