NOTE

A shop cloth should be used to divert escaping refrigerant when

disconnecting the charging hose from the Schrader valve. Recap the valve.

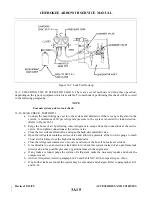

14-17. ADDITION OF PARTIAL CHARGE TO SYSTEM. It is possible to top off this system with refrigerant

by the following method.

a.

Remove the access panel at the rear of the cabin.

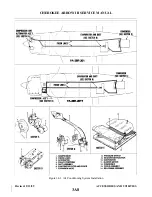

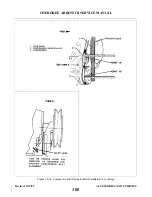

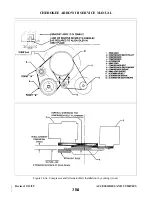

b. Connect a charging hose to a refrigerant cylinder and also to the Schrader valve fitting on the

suction line. (Refer to Figure 14-8.)

c.

Purge the charging hose by allowing a small amount of refrigerant gas to escape at the Schrader

valve fitting.

d. Start the engine and operate at 1000 rpm and turn the air conditioner on maximum cool.

e.

Remove the plastic plug from the sight glass in the top of the receiver-dehydrator.

f.

With a low refrigerant charge in the system, bubbles will be seen passing thru the sight glass when

the system is operating.

g. Open the valve on the refrigerant cylinder.

h. Allow refrigerant to flow into the system until the bubbles disappear from the sight glass.

i.

Close the refrigerant valve and check to see that the sight glass remains clear during system

operation.

j.

When the sight glass stays clear of bubbles, add an additional 1/4 pound of refrigerant to the

system. (Engine should be operating at 1000 rpm.)

NOTE

This should be done with OAT at 70°F, or higher, with the air conditioner

operating.

k. Shut off the air conditioner and engine. Remove the charging hose from the Schrader valve with

care due to refrigerant remaining in the line.

1. Replace the access panels.

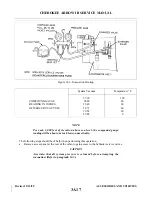

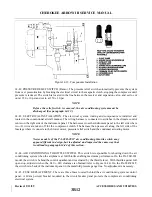

14-18. COMPRESSOR SERVICE. It is not advisable to service the compressor in the field. It should be done

by a qualified shop which has the special equipment and trained personnel required to properly service the

unit.

Maintenance of the York unit and its related components is limited to the replacement of worn drive belt

and magnetic clutch Any other service requires removal of the compressor from the system. Maintenance to

the Sankyo compressor is limited to replacement of worn drive belt. Contact Sankyo International, 3529 Miller

Park Drive, P.O. Box 2903, Garland, Texas 75042 for special tools and instructions for detailed compressor

maintenance.

NOTE

An important factor in air conditioning servicing is cleanliness and care

should be exercised to prevent dirt or foreign material from entering the

system. All hose and tubing ends should be capped immediately. Any

lubrication required in the assembly of the components should be

refrigerant oil of the type used in the compressor.

Revised: 2/13/89

3A21

CHEROKEE ARROW III SERVICE MANUAL

ACCESSORIES AND UTILITIES

Summary of Contents for ARROW III

Page 4: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A4...

Page 12: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A12...

Page 94: ...Figure 4 2 Wing Installation Revised 2 13 89 1D22 CHEROKEE ARROW III SERVICE MANUAL STRUCTURES...

Page 171: ...lH3 INTENTIONALLY LEFT BLANK...

Page 172: ...lH4 INTENTIONALLY LEFT BLANK...

Page 286: ...THIS PAGE INTENTIONALLY LEFT BLANK Revised 2 13 89 2A8...

Page 528: ...INTENTIONALLY LEFT BLANK 2K10 THRU 2L24 2K10...