WARNING

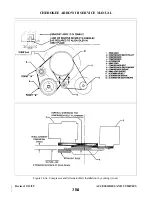

If the air conditioner is to be operated on the ground for servicing, the test

area should be clean and free of any loose objects lying on the ramp. Only

the service valves located on the evaporator assembly should be used for

testing.

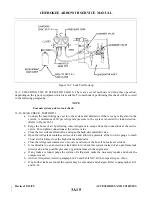

b. The installation instructions for the Sankyo compressor are as follows:

1. Place the compressor in the mounting brackets and install attachment bolts. Do not torque

attachment bolts at this time.

2. Install compressor drive belt. Rotate compressor drive belt. Rotate compressor in mounting

bracket slots to obtain a belt tension of 85 to 90 lbs. Torque the four attachment bolts 300 to

350 in.-lbs. (Also, refer to paragraph 14-23.)

3. Check the oil level in the compressor in accordance with instructions given in paragraph 14-

4. Connect the discharge and suction lines to their respective fittings.

WARNING

If the air conditioner is to be operated on the ground for servicing, the test

area should be clean and free of any loose objects lying on the ramp. Only

the service valves located on the evaporator assembly should be used for

testing.

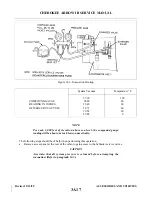

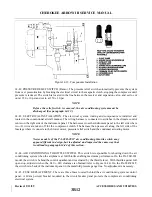

14-21. CHECK COMPRESSOR OIL. The oil level should be checked any time the system is discharged.

a.

The following steps should be followed to perform York compressor oil check.

1. It will be necessary to discharge the system. (Refer to paragraph 14-12.)

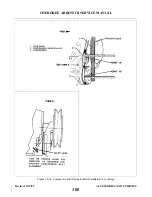

2. Fabricate an oil dipstick. (Refer to Figure 14-9.)

3. Remove the oil fill plug. (A.375 inch plug in the top side of the compressor crankcase.)

4. Before inserting the dipstick, the crankshaft Wo o d r u ff key should be located in the up

position. (The front face of the compressor clutch is marked with a stamped “K” indicating the

key position.) The oil level should be measured from the lowest point in the crankcase. Use

the long end of the dipstick. (See Figure 14-9.)

5. With the compressor in the installed position, use Table XIV-III to determine the amount of oil

in crankcase.

6. The compressor should never be operated with less than 6 ounces of oil. When oil is added,

the level should not go above 10 ounces. Piper refrigerant oil PMS-L2000 or equivalent 500

viscosity refrigerant oil must be used.

7. Evacuate and charge system. (Per paragraphs 14-13 and 14-14.)

NOTE

The 10 ounce oil level is required in compressors installed on new systems.

Some oil is distributed in the system during operation. Replacement

compressors should be charged with 10 ounces of oil.

CAUTION

The oil plug should not be removed with pressure in the system.

Revised: 2/13/89

3A23

CHEROKEE ARROW III SERVICE MANUAL

ACCESSORIES AND UTILITIES

Summary of Contents for ARROW III

Page 4: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A4...

Page 12: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A12...

Page 94: ...Figure 4 2 Wing Installation Revised 2 13 89 1D22 CHEROKEE ARROW III SERVICE MANUAL STRUCTURES...

Page 171: ...lH3 INTENTIONALLY LEFT BLANK...

Page 172: ...lH4 INTENTIONALLY LEFT BLANK...

Page 286: ...THIS PAGE INTENTIONALLY LEFT BLANK Revised 2 13 89 2A8...

Page 528: ...INTENTIONALLY LEFT BLANK 2K10 THRU 2L24 2K10...