14-61. LEAK TESTS. Solutions recommended for leak testing are Leak-Tec Formula #16-OX and that

available from Scott Aviation. Refer to the List of Consumable Materials for consumer information.

1. Remove royalite covers in baggage compartment and with the oxygen system turned off, disconnect

low pressure supply line and connect it to a regulated cylinder charged with dry nitrogen.

CAUTION

Whenever a leak check is performed, all fitting connections as well as other

questionable areas, should be inspected.

2. Apply the leak detector solution to test surface and watch for indication of leakage.

3. L a rge leaks will produce bubbles immediately, but small leaks will form a white foam in 5 to 60

seconds.

4. With outlets vacated of masks, connect a test pressure gauge to the copilot’s outlet. See Figure 14-17.

5. Adjust regulator on dry nitrogen cylinder for 100 psi and check for leakage at the outlets.

6. Correct any leaks and wipe off excess leak detector solution.

7. Close valve on nitrogen gas tank and insert a Scott plug-in to relieve system pressure.

8. Disconnect test gauge, plug-in, and nitrogen tank.

9. If the oxygen cylinder is not to be hooked up or installed immediately, cap and cover exposed fittings

with new clean plastic bags. Temporarily support lines as needed to prevent damage. Make sure caps

and coverings are as clean as possible.

14-62. OXYGEN SYSTEM COMPONENT HANDLING.

WARNING

All oxygen components must be handled carefully. Ports on regulators,

indicators, and other opened components must be kept capped or plugged.

Adjustments or modifications should only be initiated under direction of the

FAA, Scott Aviation, and Piper Aircraft.

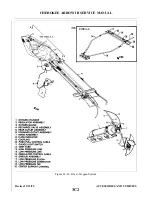

14-63. REMOVAL OF OXYGEN CYLINDER. (Refer to Figure 14-16.)

CAUTION

When working in tail cone, attach tail stand to tail.

NOTE

Replacement time for the recharge valve is every 5 years. If the cylinder is

being removed for the 5 year test, it is recommended the valve be removed

and/or replaced at the same time.

The oxygen bottle, located behind the finished bulkhead in the baggage compartment, is secured to a

removable shelf mounted to each side of the fuselage. The tank is mounted such that the regulator- c o n t r o l

valve is on the left side of the aircraft (the same side as the recharge valve). A shroud also covers the regulator

end of the bottle to prevent leaks, should any develop, firm filling the aircraft with oxygen. With this in mind,

a vent tube interconnects the shroud with the recharge valve fixture permitting any oxygen to vent overboard.

1. Remove screws attaching finished bulkhead to fuselage bulkhead and remove finished bulkhead.

Revised: 2/13/89

3C9

CHEROKEE ARROW III SERVICE MANUAL

ACCESSORIES AND UTILITIES

Summary of Contents for ARROW III

Page 4: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A4...

Page 12: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A12...

Page 94: ...Figure 4 2 Wing Installation Revised 2 13 89 1D22 CHEROKEE ARROW III SERVICE MANUAL STRUCTURES...

Page 171: ...lH3 INTENTIONALLY LEFT BLANK...

Page 172: ...lH4 INTENTIONALLY LEFT BLANK...

Page 286: ...THIS PAGE INTENTIONALLY LEFT BLANK Revised 2 13 89 2A8...

Page 528: ...INTENTIONALLY LEFT BLANK 2K10 THRU 2L24 2K10...