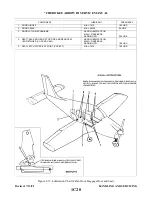

3-5. PREFLIGHT INSPECTION. This inspection is for the pilot/or mechanic and should become part of the

airplane operational routine and/or preflight inspection before each flight.

a.

The propeller blade is free of nicks and the spinner and hub free of cracks or damage.

b. The engine oil is at the proper level.

c.

There are no obvious oil leaks.

d. The cowling is clean. There are no loose or missing fasteners and all inspection covers are secured.

e.

There are no foreign objects in the engine compartment or obstructions in the air intakes, and cylinder

b a ffle seals on left and right side are properly positioned. Seals should be rolled up against inner

surface of upper cowl.

f.

The tires are properly inflated and not excessively worn or cut.

g. The landing gear oleo struts have proper extension.

h. The brakes are working and there are no obvious leaks.

i.

The fuel tanks are full or at a safe level of proper fuel.

j.

There are no visible leaks in the fuel system.

k. The fuel tank caps are secure and the vents are open.

1. The fuel tanks and sediment bowls, strainers and lines are free of water and sediment by draining

sumps and strainers.

m. There is no external damage, cracks or operational interference to the control surfaces, wings or

fuselage.

n. The windshield and windows are free of defects and clean.

o. The baggage door latch, hinges, and cabin entrance door and window are free of damage and operate

properly.

p. The seats and seat belts are securely fastened.

q. The landing, navigation, and cabin instrument lights are all operating.

r.

The fuel selector valve is operating properly.

s.

The throttle, mixture and propeller controls are all operating properly.

t.

All systems are operating properly.

3-6. OVERLIMIT INSPECTION. If the airplane has been operated so that any of its components have

exceeded their maximum operational limits, check with the appropriate manufacturer.

3-7. SPECIAL INSPECTIONS. The special inspections given in the following paragraphs, supplement the

scheduled inspections as outlined in the Inspection Report, Table III-I, to include inspection of items which are

required to be examined at intervals not compatible with airframe operating time or airframe inspection

intervals. Typical of this type are:

a.

Inspection required because of special conditions or incidents that arise, and because of these

conditions or incidents, an immediate inspection would be required to ensure further safe flight.

b. Inspection of airframe or components on a calendar basis. This type of inspection could often be

accomplished during the nearest scheduled inspection.

c.

Specific definitive inspection on engines based strictly upon engine operating time.

d. Those inspections not completely covered in other sections of this manual, but outlined in the

Inspection Report and must be explained in more detail to give a clearer and complete inspection.

3-8. SERVICE PUBLICATION COMPLIANCE REQUIREMENTS. Piper Service Publications are

recommended and/or mandatory changes to Piper aircraft. “Piper Service Bulletins are of Special Importance

and Piper considers compliance mandatory”.

Revised: 2/13/89

1D3

* CHEROKEE ARROW III SERVICE MANUAL

INSPECTION

Summary of Contents for ARROW III

Page 4: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A4...

Page 12: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A12...

Page 94: ...Figure 4 2 Wing Installation Revised 2 13 89 1D22 CHEROKEE ARROW III SERVICE MANUAL STRUCTURES...

Page 171: ...lH3 INTENTIONALLY LEFT BLANK...

Page 172: ...lH4 INTENTIONALLY LEFT BLANK...

Page 286: ...THIS PAGE INTENTIONALLY LEFT BLANK Revised 2 13 89 2A8...

Page 528: ...INTENTIONALLY LEFT BLANK 2K10 THRU 2L24 2K10...