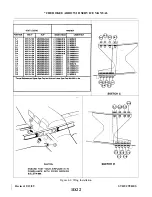

TABLE III-I. INSPECTION REPORT (cont)

Nature of Inspection

D. ENGINE GROUP (LYCOMING)

4. Clean oil suction and oil pressure strainers at oil

change (Inspect strainers for foreign particles).........................................................

O

O

O

5. Change full flow (cartridge type) oil filter element

(inspect element thoroughly for foreign particles.....................................................

O

O

O

O

6. Inspect oil temperature sender unit for leaks and

security......................................................................................................................

O

O

O

7. Inspect oil lines, hoses, and fittings for leaks, security,

chafing, dents, and cracks (Read Note 6) .................................................................

O

O

O

O

8. Clean and inspect oil radiator cooling fins. Verify that

there is no radiator damage.......................................................................................

O

O

O

9. Remove and flush oil radiator...................................................................................

O

O

O

10.Fill engine with oil per lubrication chart in Service

Manual, Section II.....................................................................................................

O

O

O

CAUTION

Prior to cleaning engine, use caution not to

contaminate vacuum pump(s) with cleaning fluid

Cap all openings. (Refer to latest revision of

Lycoming Service Instruction 1221).

11.Clean engine .............................................................................................................

O

O

O

12.Inspect condition of spark plugs (clean and adjust as required. (Refer to

latest revision of Lycoming Service Instruction 1042..............................................

O

O

O

NOTE

If fouling of spark plugs are apparent, rotate bottom

plugs to upper plugs, and visa versa.

13.Inspect spark plug harness leads and ceramics for corrosion and deposits..............

O

O

O

O

14.Check cylinder compression (Refer to latest revision of Lycoming

Service Instruction 1042)..........................................................................................

O

O

O

15.Inspect cylinders for cracked or broken fins (Read Note 10)...................................

O

O

O

16.Inspect rocker box covers for evidence of oil leaks. If found, replace

gasket(s); Torque cover screws 50 inch-pounds (Read Note 9) ...............................

O

O

O

O

NOTE

Lycoming requires a valve inspection after every 400

hours of engine operation. (Read Note 9 )

50

500

1000

100

Inspection Time (HRS)

CHEROKEE ARROW III SERVICE MANUAL

1D8

Revised 2/13/89

INSPECTION

Summary of Contents for ARROW III

Page 4: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A4...

Page 12: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A12...

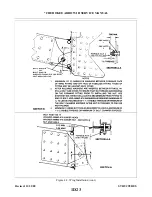

Page 94: ...Figure 4 2 Wing Installation Revised 2 13 89 1D22 CHEROKEE ARROW III SERVICE MANUAL STRUCTURES...

Page 171: ...lH3 INTENTIONALLY LEFT BLANK...

Page 172: ...lH4 INTENTIONALLY LEFT BLANK...

Page 286: ...THIS PAGE INTENTIONALLY LEFT BLANK Revised 2 13 89 2A8...

Page 528: ...INTENTIONALLY LEFT BLANK 2K10 THRU 2L24 2K10...