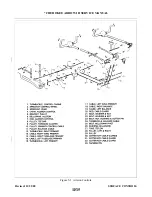

5-12. RIGGING AND ADJUSTMENT OF AILERON CONTROLS. (Refer to Figures 5-3 thru 5-4.)

NOTE

Flap adjustment must be complete before starting aileron adjustment.

a.

To check and adjust the rigging of the aileron controls, first set the right and left aileron bellcranks at

neutral position. (Ascertain that the control chains have been rigged per Paragraph 5-6.) This may be

accomplished by the following procedure:

l.

Place tee bar in full forward position, and maintain it in this position by use of a suitable tool or

by placing weights on the aft side of the stabilator if the stabilator cables have been previously

tensioned.

2. Remove the access plate to each aileron bellcrank located on the underside of the wing, forward of

the inboard end of the aileron by removing the plate attaching screws.

3. Affix a bellcrank rigging tool, as shown in Figure 5-3, between the forward arm of each bellcrank

and the adjacent outboard rib. (This tool may be fabricated from dimensions given in Figure 5-18.)

The slotted end of the tool fits on the arm forward of and adjacent to the primary control cable

end. The other end of the tool is positioned so that the side of the tool contacts the aft side of the

bellcrank stop. The bellcrank must be moved to allow a snug fit of the tool between the bellcrank

arm and rib. To do so, it may be necessary to loosen a primary control cable or the balance cable.

Neutral position of the bellcranks may also be found by locating the position at which the forward

and aft cable connection holes are an equal distance from the adjacent outboard wing rib.

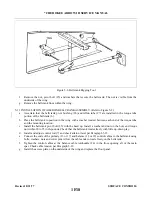

b. With each bellcrank set at neutral, the ailerons may be checked and adjusted for neutral as follows:

1. Ascertain that the bellcrank rigging tool fits snug between the bellcrank and the rib.

2. Place an aileron rigging tool as shown in Figure 5-4 against the underside of the wing and aileron

as close as possible to the inboard end of the aileron without contacting any rivets. The tool must

be positioned parallel with the wing ribs, with the aft end of the tool even with the trailing edge of

the aileron. (This tool may be fabricated from dimensions given in Figure 5-19.)

3. With the aileron control rod connected between the bellcrank and aileron, check that the surface of

the wing contacts the tool at its forward surface and at the spacer, and the trailing edge of the flap

contacts the aft end of the tool. The aileron is neutral at this position.

4. Should the three points not contact; loosen the jam nut at the aft end of the control rod and rotate

the rod until the three points contact. Apply a slight up pressure against the trailing edge of the

aileron while making this adjustment. The aileron may be allowed to “droop” by approximately

1/8’’ of an inch at the inboard trailing edge. After adjustment, retighten the jam nut.

c.

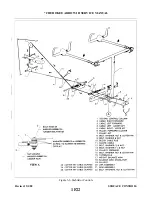

Adjust primary and balance cable tension as given in Table V-l by the following procedure:

1. Remove the two front seats, if desired, and the rear seat floor panel to facilitate in the necessary

operation.

2. Loosen the connecting bolts of the idler cross-over sprockets at the control tee bar to allow the

chain to fit snug around the control wheel sprockets and over the idler sprockets.

3. Ascertain that both bellcranks are at neutral position.

4. Adjust the turnbuckles, located in the access opening just aft of the main spar, of the primary and

balance cables to their proper cable tension and maintain neutral-center position of the control

wheels. Primary cable tension will be slightly less than balance cable tension, but still should be

within the tension specified. Adjust the cables so that the inboard end of the ailerons visually lines

up with the outboard end of the flap when a slight up pressure is applied to the middle of the

aileron to take the slack out of the hinge and linkage. To obtain neutral position of both control

wheels, it may also be necessary to adjust the roller chain turnbuckle located between the control

wheel sprockets. During adjustment, obtain a little more tension oh the primary control cables to

hold the bellcranks in neutral against the rigging tools, finishing with even tension on all cables.

Revised: 5/1/80

1F19

* CHEROKEE ARROW III SERVICE MANUAL

SURFACE CONTROLS

Summary of Contents for ARROW III

Page 4: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A4...

Page 12: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A12...

Page 94: ...Figure 4 2 Wing Installation Revised 2 13 89 1D22 CHEROKEE ARROW III SERVICE MANUAL STRUCTURES...

Page 171: ...lH3 INTENTIONALLY LEFT BLANK...

Page 172: ...lH4 INTENTIONALLY LEFT BLANK...

Page 286: ...THIS PAGE INTENTIONALLY LEFT BLANK Revised 2 13 89 2A8...

Page 528: ...INTENTIONALLY LEFT BLANK 2K10 THRU 2L24 2K10...