TABLE VI-I. LEADING PARTICULARS, HYDRAULIC SYSTEM

Hydraulic

PRESTOLITE

OILDYNE

High Pressure

2250 +/-250 psi

2400 +/-200 psi

Low Pressure

650 +/-150 psi

600 +/-200 psi

Flow Rate @ 1000 psi

45 cu. in. per min.

60cu.in.per min.

High Pressure Control

1600 to 2000 psi

2400 +/-200 psi

Thermal Relief

2250 +/-250 psi

3000 + 300-200 psi

Hydraulic Fluid

MIL-H-5606A

MIL-H-5606

Pressure Switch

Open (OFF) Pressure

1800 +/-100 psi

Close (ON) Pressure

300 +/-psi below opening pressure

6-4. HYDRAULIC PUMP. (PRESTOLITE, OILDYNE)

6-5. REMOVAL OF HYDRAULIC PUMP. The hydraulic pump with reservoir incorporated is located in the

aft section of the fuselage. Access to the pump is through the access panel in the aft wall of the baggage

compartment.

a.

Disconnect the pump electrical leads from the pump solenoid relays and the ground wire from the

battery shelf.

b. Disconnect the hydraulic lines from the pump. Cap the line ends to prevent contamination.

c.

Remove the pump by removing the pump attaching bolts.

WARNING

When servicing or inspecting vendor equipment installed in Piper aircraft, it

is the user’s responsibility to refer to the applicable vendor publication.

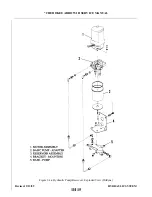

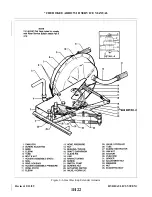

6-6. DISASSEMBLY OF HYDRAULIC PUMP. (PRESTOLITE) (Refer to Figure 6-3.) After the hydraulic

pump has been removed from the airplane, cap or plug all ports and clean the exterior of the pump with a dry

type solvent to remove accumulated dust or dirt. To disassemble any one of the three main components of the

pump, proceed as follows:

a.

The base (16) of the pump may be removed from the case (15) as follows:

1. Cut the safety wire and remove the bolts (17) with washers that secure the base to the pump case.

2. The shuttle valve within the base should be removed for cleaning purposes only. To remove the

valve, cut safety wire. Remove plug with spring and valve.

NOTE

The shuttle valve and pump base are matched, lapped parts. Should it be

necessary to replace, replace as an assembly only.

b. Pump Motor: The pump motor may be removed from the pump and disassembled as follows:

1. Remove thru bolts (4) from head (1) of motor. Using a knife, cut the seal coating between the

motor head and case.

2. Lift the head up from the case approximately .50 of an inch, this will allow inspection of brushes

(3) without the brushes unseating from the commutator. (Refer to Paragraph 6-7, b for brush

inspection.) The brush heads are secured to the head assembly.

3. Raise the head assembly (1) off the armature (8) and note the small thrust ball (7) located between

the end of the armature (8) and motor head. Do not misplace this bearing.

Revised: 2/13/89

1H12

* CHEROKEE ARROW III SERVICE MANUAL

HYDRAULIC SYSTEM

Summary of Contents for ARROW III

Page 4: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A4...

Page 12: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A12...

Page 94: ...Figure 4 2 Wing Installation Revised 2 13 89 1D22 CHEROKEE ARROW III SERVICE MANUAL STRUCTURES...

Page 171: ...lH3 INTENTIONALLY LEFT BLANK...

Page 172: ...lH4 INTENTIONALLY LEFT BLANK...

Page 286: ...THIS PAGE INTENTIONALLY LEFT BLANK Revised 2 13 89 2A8...

Page 528: ...INTENTIONALLY LEFT BLANK 2K10 THRU 2L24 2K10...