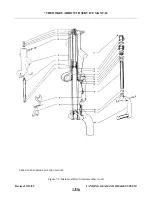

to manually overcome system malfunctions or to meet special pilot needs such as a deliberate wheels up landing

needed for emergency landings on water, or during various flight maneuvers where airspeed and power settings

would normally allow the gear to extend. It also permits gear retraction after takeoff at speeds lower than those

normally permitted by the automatic system. When using the manual extension lever, the gear position is

controlled by the selector switch, regardless of airspeed/power combinations. An override latch mechanism is

installed which allows the pilot to latch the extension lever in the up override position, thus bypassing the

automatic portion of the system on airplanes that have operational back-up gear extender systems. A flashing

warning light is mounted below the gear selector lever to indicate whenever the latch is in use. The latch is

disengaged by pulling up on the extension lever. To assist the nose gear to extend under these conditions are two

springs, one inside the other, mounted on arms above the gear links. The main gears require no assist springs.

Once the gears are down and the downlock hooks engage, a spring maintains each hook in the locked position

until hydraulic pressure again releases it. A further description of the hydraulic system and the gear back-up

extender unit may be found in Section VI, Hydraulic System.

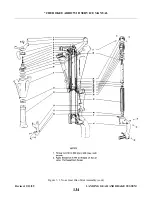

The nose gear is steerable through a 60 degree arc by the use of the rudder pedals. As the gear retracts,

h o w e v e r, the steering linkage becomes separated from the gear so that rudder pedal action with the gear retracted

is not impeded by the nose gear operation. A shimmy dampener is also incorporated in the nose wheel steering

mechanism. Bungee springs are also incorporated on the push rods. These springs make lighter and smoother

ground steering possible.

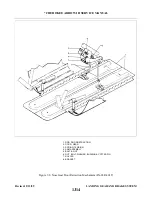

The two main wheels are equipped with self-adjusting single disc hydraulic brake assemblies. Toe brakes are

standard on both the pilot’s and copilot’s rudder pedals. A parking brake is incorporated with the handle, and may

be used by pulling back on the handle and pushing forward on the button to the left of the handle. To release the

hand brake, pull aft on the handle and allow it to swing forward. Hydraulic fluid for the cylinders is supplied by a

reservoir installed on the left forward side of the firewall.

WA R N I N G

Place airplane on jacks prior to troubleshooting landing gear system.

7-3. TROUBLESHOOTING. Mechanical and electrical switch troubles peculiar to the landing gear system are

listed in Table VII-II at the back of this section. When troubleshooting, first eliminate hydraulic malfunctions as

listed in Section VI. Then proceed to switch malfunctions and last to the mechanical operation of the gear itself,

both of which are listed in this section. Always place the airplane on jacks before attempting any troubleshooting

of the gear. To operate the gear, the emergency gear lever must be maintained in the up override position.

7-4. LANDING GEAR SYSTEM.

7-5. NOSE LANDING GEAR.

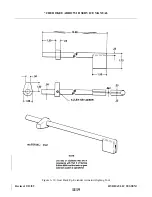

7-6. DISASSEMBLY OF NOSE GEAR OLEO. (Refer to Figure 7-1.) The nose gear oleo assembly may be

removed and disassembled from the gear oleo housing with the gear removed from or installed on the airplane.

a .

Place the airplane on jacks. (Refer to Jacking, Section II.)

b . Place a drip pan under the nose gear to catch spillage.

c .

Remove air and fluid from the oleo strut. Depress the air valve core pin until strut chamber pressure has

diminished, remove the filler plug and with a small hose siphon as much hydraulic fluid from the strut as

p o s s i b l e .

top of the unit and remove cap bolts (1) that attach steering arm (11) and aligner guide bracket (12) to the

top of the oleo cylinder (23).

e .

Disconnect the shimmy dampener by removing each cotter pin, nut, washer and bolt that connects the

dampener to the oleo cylinder (23) and housing.

f .

Release and remove the snap ring (17) and washer(s) (43), if installed, at the top of the housing (21), and

pull the complete cylinder and fork assembly from the bottom of the housing. The upper and lower

housing bushings (20 and 22) should remain pressed in the housing.

Revised: 2/13/89

1J1

* CHEROKEE ARROW III SERVICE MANUAL

LANDING GEAR AND BRAKE SYSTEM

Summary of Contents for ARROW III

Page 4: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A4...

Page 12: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A12...

Page 94: ...Figure 4 2 Wing Installation Revised 2 13 89 1D22 CHEROKEE ARROW III SERVICE MANUAL STRUCTURES...

Page 171: ...lH3 INTENTIONALLY LEFT BLANK...

Page 172: ...lH4 INTENTIONALLY LEFT BLANK...

Page 286: ...THIS PAGE INTENTIONALLY LEFT BLANK Revised 2 13 89 2A8...

Page 528: ...INTENTIONALLY LEFT BLANK 2K10 THRU 2L24 2K10...