7-66. CLEANING, INSPECTION AND REPAIR OF BRAKE CYLINDER

a.

Clean cylinder components with a suitable solvent and dry thoroughly.

b. Inspect interior walls of cylinder for scratches, burrs, corrosion, etc.

c.

Inspect general condition of fitting threads.

d. Inspect piston for scratches, burrs, corrosion, etc.

e.

Repairs to the cylinder are limited to polishing out small scratches and burrs and replacing seal and O-

rings.

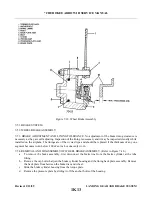

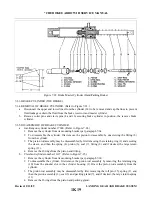

7-67. ASSEMBLY OF BRAKE CYLINDER. (Refer to Figures 7-24 and 7-25.)

NOTE

Rub a small amount of hydraulic fluid (MIL-H-5606) on all O-rings and

component parts for ease of handling during reassembly and to prevent

damage.

a.

Gar-Kenyon cylinder number 17000. (Refer to Figure 7-24.)

1. Install new O-rings on the inside and outside of the fitting (8) and on the outside of the piston (6).

2. To assemble the piston rod assembly, install on the rod (12), in order, the roll pin (14), return

3. Insert the piston rod assembly in the cylinder (1) and secure fitting (8).

4. Install the cylinder per paragraph 7-68.

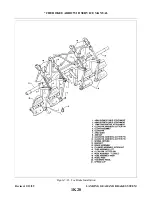

b. Cleveland cylinder number 10-27. (Refer to Figure 7-25.)

1. Install new O-rings on the inside and outside of the packing gland (7) and on the outside of the

2. To assemble the piston rod assembly, install on the rod (12), in order, the roll pin (14), washer

3. Insert the piston rod assembly in the cylinder (1) and secure with the retaining ring (10).

4. Install the cylinder per paragraph 7-68.

7-68. INSTALLATION OF BRAKE CYLINDER. (Refer to Figure 7-24.)

a.

Position brake cylinder (14) at its mounting points and secure in position with clevis pin (4 and 16).

Safety clevis pin with cotter pins.

b. Connect brake lines to cylinder fittings. Bleed brakes as explained in paragraph 7-69 or 7-70.

7-69. BLEEDING BRAKES.

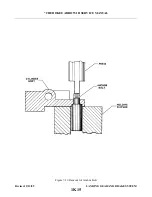

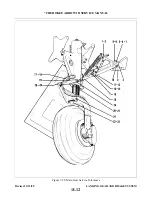

7-70. BRAKE BLEEDING PROCEDURE (Gravity). (Refer to Figure 7-26.)

a.

On both main landing gear wheel brake assemblies, attach a clear plastic hose to the brake bleeders

and extend into container partially filled with hydraulic fluid, MIL-H-5606. The ends of this hose

should be submerged in the fluid. Open both bleeders approximately one and one-half to two turns.

b. Fill the brake reservoir on the firewall with hydraulic fluid, MIL-H-5606.

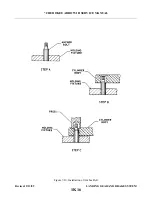

c.

Disconnect the toe brake cylinders from the pedal connection by removing clevis pin, washer and

cotter pin.

d. Invert toe brake cylinder to aid in releasing trapped air in the top of the cylinder.

e.

Check toe brake pedals in the cockpit to ensure pedals are pulled full aft

f.

Pull the hand brake handle, pumping the master cylinder very slowly approximately 25 times until

fluid is observed passing through the clear plastic hoses at the wheel cylinder.

Revised: 2/13/89

1K22

* CHEROKEE ARROW III SERVICE MANUAL

LANDING GEAR AND BRAKE SYSTEM

Summary of Contents for ARROW III

Page 4: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A4...

Page 12: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A12...

Page 94: ...Figure 4 2 Wing Installation Revised 2 13 89 1D22 CHEROKEE ARROW III SERVICE MANUAL STRUCTURES...

Page 171: ...lH3 INTENTIONALLY LEFT BLANK...

Page 172: ...lH4 INTENTIONALLY LEFT BLANK...

Page 286: ...THIS PAGE INTENTIONALLY LEFT BLANK Revised 2 13 89 2A8...

Page 528: ...INTENTIONALLY LEFT BLANK 2K10 THRU 2L24 2K10...