8-43. MAINTENANCE OF HARNESS.

a.

To replace contact springs, spring retainer assemblies or insulating sleeves, proceed as follows:

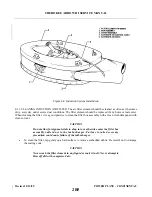

1. Using a Bendix 11-7073 Needle or a mechanical pencil with the lead retracted, hook the end of the

contact spring as shown in Figure 8-18.

2. Using the needle or pencil, unscrew the spring.

3. Slide the insulating sleeve and spring retainer assembly off the end of the lead assembly.

4. Replace the defective component and reassemble as follows:

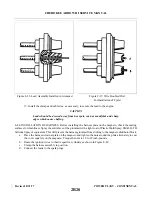

(a) Fabricate a tool as shown in Figure 8-19 for installing the insulating sleeves over the cable

terminals.

(b) Push the tool through insulating sleeve and spring retainer assembly as shown in Figure 8-20.

Screw the cable terminal into the tool.

(c) Work the insulating sleeve and spring retainer assembly into position over the cable and

unscrew the tool. Install the contact spring on the cable terminal.

NOTE

It may be necessary to lubricate the cable and insulating sleeve with a thin

film of Dow-Corning 200 (200,000 centi-stokes) or commercial grade

alcohol to facilitate assembly.

b. To replace one of the lead assemblies, proceed as follows:

1. Remove the clamps and brackets from the applicable lead assembly. Cut the cable ties from the

assembly and discard them.

2. Cut off the condemned lead flush with the outer surface of the cable outlet plate.

3. Grip the eyelet of the lead with a pair of pliers and pull the short length of conductor out of

grommet and cable outlet plate.

4. Using a 3 inch long, 0.270 of an inch diameter drift applied at outer surface of plate, drive out

tapered ferrule and remaining pieces of insulation and shielding.

5. To determine what length the new lead assembly should be cut to, proceed as follows:

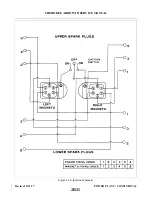

(a) Measure the length of the condemned lead assembly. Move the coupling nut back on the lead

assembly and measure from the outer end of the ferrule at the spark plug end. (Refer to

Figure 8-21.)

NOTE

Spare part leads are supplied in various lengths. Use a lead which is longer

than, but nearest to, the desired length.

6. Cut the lead assembly to the length determined in Step 5. Mark the ferrule on the spark plug end of

the lead with a metal stamp, scribe or rubber stamp to correspond with the correct cylinder

number.

7. Starting at the spark plug location, thread the new cable through the grommets and clamps as

necessary for the correct routing of the cut end of the cable to the magneto location.

8. Remove the cable outlet plate from the magneto. Support the plate securely and using suitable

cutting pliers, split and remove the eyelets from the leads adjacent to the lead being replaced.

When splitting the eyelet, make certain that the wire strands are not cut. Removal of eyelets on

adjacent leads will allow the grommet to be pulled away from the outlet plate to facilitate insertion

of the new lead.

9. Assemble the lead to the cable outlet plate following the procedure in Steps 10 through 17.

Revised: 8/31/77

2B16

CHEROKEE ARROW III SERVICE MANUAL

POWER PLANT - CONTINENTAL

Summary of Contents for ARROW III

Page 4: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A4...

Page 12: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A12...

Page 94: ...Figure 4 2 Wing Installation Revised 2 13 89 1D22 CHEROKEE ARROW III SERVICE MANUAL STRUCTURES...

Page 171: ...lH3 INTENTIONALLY LEFT BLANK...

Page 172: ...lH4 INTENTIONALLY LEFT BLANK...

Page 286: ...THIS PAGE INTENTIONALLY LEFT BLANK Revised 2 13 89 2A8...

Page 528: ...INTENTIONALLY LEFT BLANK 2K10 THRU 2L24 2K10...