8-59. ENGINE AND PROPELLER CONTROLS.

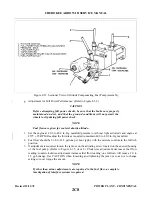

8-60. RIGGING THROTTLE, MIXTURE AND GOVERNOR CONTROLS. (Refer to Figure 8-33.)

a.

Rig the throttle control as follows:

1. Place the quadrant throttle lever full forward.

2. With the control arm on the fuel-air control unit in the full throttle position. rig the throttle

quadrant lever to provide a minimum of .032 inches clearance from the forward stop. With the

control arm at the idle stop, the quadrant throttle lever must have a minimum clearance of .032

inches from the aft stop.

3. Rig the aft throttle micro-switch to actuate the gear warning horn and red light at a manifold

pressure of 14 ± 2 inches with the landing gear retracted.

b.

Rig the propeller control as follows:

1. Place the propeller control lever full forward.

2. With the propeller governor control arm in the low pitch (high RPM) position, rig the quadrant

control lever to provide .047/.032 inches clearance from the forward stop.

c.

Rig the mixture control as follows:

NOTE: Check the routing and security of the mixture cable to prevent interference between the cable and

the gear linkage.

1. Place the mixture control lever full forward.

2. With the mixture control arm on the engine fuel pump in the full rich position, rig the quadrant

mixture lever to provide a minimum of .032 inches clearance from the forward stop.

3. With the mixture control arm at idle cut-off, the quadrant mixture lever must have a minimum of

.032 inches clearance from the aft stop.

8-61. ENGINE SETUP PROCEDURES. The following procedures should be used to check and adjust the

power plant to maintain the required operating limits and insure obtaining good setup results. It is important

that the following leak check be made before proceeding with any actual system adjustments:

a.

Leak Check - Gauge Lines:

1. Disconnect the manifold pressure, deck pressure, and fuel pressure lines on the forward side of the

rear engine baffle.

2. Connect surgical tubing to the fuel flow (deck pressure) bulkhead fitting and evacuate the line until

a 10 gallon per hour (maximum) positive indication on the fuel flow gauge is obtained. Clamp off

the tubing and observe the gauge for a steady reading. Any change of this reading would indicate a

leak in the system, which must be repaired prior to continuing with the setup procedures.

NOTE: A static system test unit can be-used to leak check these lines.

3. Check the fuel pressure and manifold pressure lines in the same manner as given in Step 2, except

apply positive pressure to the lines. Do not exceed 4 pounds per square inch (psi) on the fuel

pressure gauge, or 4 inches of mercury (In. Hg) increase on the manifold pressure gauge.

4. Visually inspect manifold pressure, deck pressure and fuel pressure lines forward of the engine

rear baffle for general condition which could cause leakage. Check all “B” nuts for tightness.

5. Reconnect the manifold pressure, fuel flow and fuel pressure lines at the bulkhead fitting.

6. Disconnect the main fuel supply line to the engine driven fuel pump, at the rear engine baffle and

using the auxiliary fuel pump, pump out approximately one quart of gasoline; then reconnect the

line.

7. Using the electric fuel boost pump, purge the air from the fuel flow gauge line at the back of the

instrument; then reconnect the line.

Revised: 02/27/04

2C5

CHEROKEE ARROW III SERVICE MANUAL

POWER PLANT - CONTINENTAL

Summary of Contents for ARROW III

Page 4: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A4...

Page 12: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A12...

Page 94: ...Figure 4 2 Wing Installation Revised 2 13 89 1D22 CHEROKEE ARROW III SERVICE MANUAL STRUCTURES...

Page 171: ...lH3 INTENTIONALLY LEFT BLANK...

Page 172: ...lH4 INTENTIONALLY LEFT BLANK...

Page 286: ...THIS PAGE INTENTIONALLY LEFT BLANK Revised 2 13 89 2A8...

Page 528: ...INTENTIONALLY LEFT BLANK 2K10 THRU 2L24 2K10...