3. Secure all excess lead wire.

4. Now remove the top engine cowling.

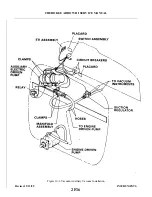

5. Mount auxiliary vacuum pump/motor assembly with band clamps. Do not tighten the clamps at

this time because adjustments may be necessary.

6. Attach and secure electrical leads to terminals on pump/motor assembly.

7. Measure hoses to obtain proper length. Allow some slack, then cut as necessary.

8. Remove all caps and plugs then attach and secure hoses to ports on pump/motor assembly.

9. Position pump/motor assembly per Figure 10-3 instructions.

10. Tighten clamps and install engine top cowling.

10-13. VACUUM REGULATOR VALVE. (Refer to Table X-I for Troubleshooting Instructions.) One vacuum

regulator valve is incorporated in the system to control vacuum pressure to the gyro instruments. The regulator

valve is located under the instrument panel. Access to the valve for maintenance and adjustment is gained from

below the instrument panel.

10-14. ADJUSTMENT OF VACUUM REGULATOR VALVE.

WARNING

Do not attempt adjustment of this valve with engine in operation. This

procedure may be done with the engine running provided a qualified pilot

or maintenance person is at the controls, but is considered dangerous and

not recommended by Piper.

CAUTION

Before any adjustments are made to the vacuum regulator, verify that the

system filters and lines are clean.

a.

Bend locking tabs up (if applicable) then loosen locking nut or remove protective cap from valve per

type installed.

b. Start the engine and allow for engine warm-up at a medium rpm setting.

c.

With the engine running at medium rpm, the suction gauge should indicate 5.0 ± 0.2 inches of

m e r c u r y. If the indication is not within this range, shut down the engine and adjust regulator

(clockwise to increase pressure or counterclockwise to decrease pressure).

d. Again, start the engine and repeat this procedure until an indication of 5.0 ± 0.2 inches of mercury is

obtained at a medium power setting.

NOTE

If airplane is not equipped with a suction gauge, connect a temporary gauge

of known accuracy by removing the plug from back of the artificial horizon

and attaching it there.

e.

After satisfied that pressure is adjusted correctly to 5.0 ± 0.2 inches of mercury, remove gauge and

install plug; replace protective cap and tighten locknut per type valve installed.

10-15. REMOVAL AND REPLACEMENT OF REGULATOR VALVE.

a.

Disconnect the three lines and remove mounting nut. Remove valve from airplane.

b. Install regulator in reverse order of removal.

c.

Verify that complete vacuum system is operational.

Revised: 2/13/89

2F18

CHEROKEE ARROW III SERVICE MANUAL

INSTRUMENTS

Summary of Contents for ARROW III

Page 4: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A4...

Page 12: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A12...

Page 94: ...Figure 4 2 Wing Installation Revised 2 13 89 1D22 CHEROKEE ARROW III SERVICE MANUAL STRUCTURES...

Page 171: ...lH3 INTENTIONALLY LEFT BLANK...

Page 172: ...lH4 INTENTIONALLY LEFT BLANK...

Page 286: ...THIS PAGE INTENTIONALLY LEFT BLANK Revised 2 13 89 2A8...

Page 528: ...INTENTIONALLY LEFT BLANK 2K10 THRU 2L24 2K10...