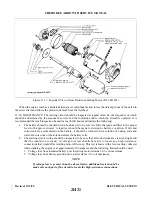

Figure 11-26. Removal of Drive End Head

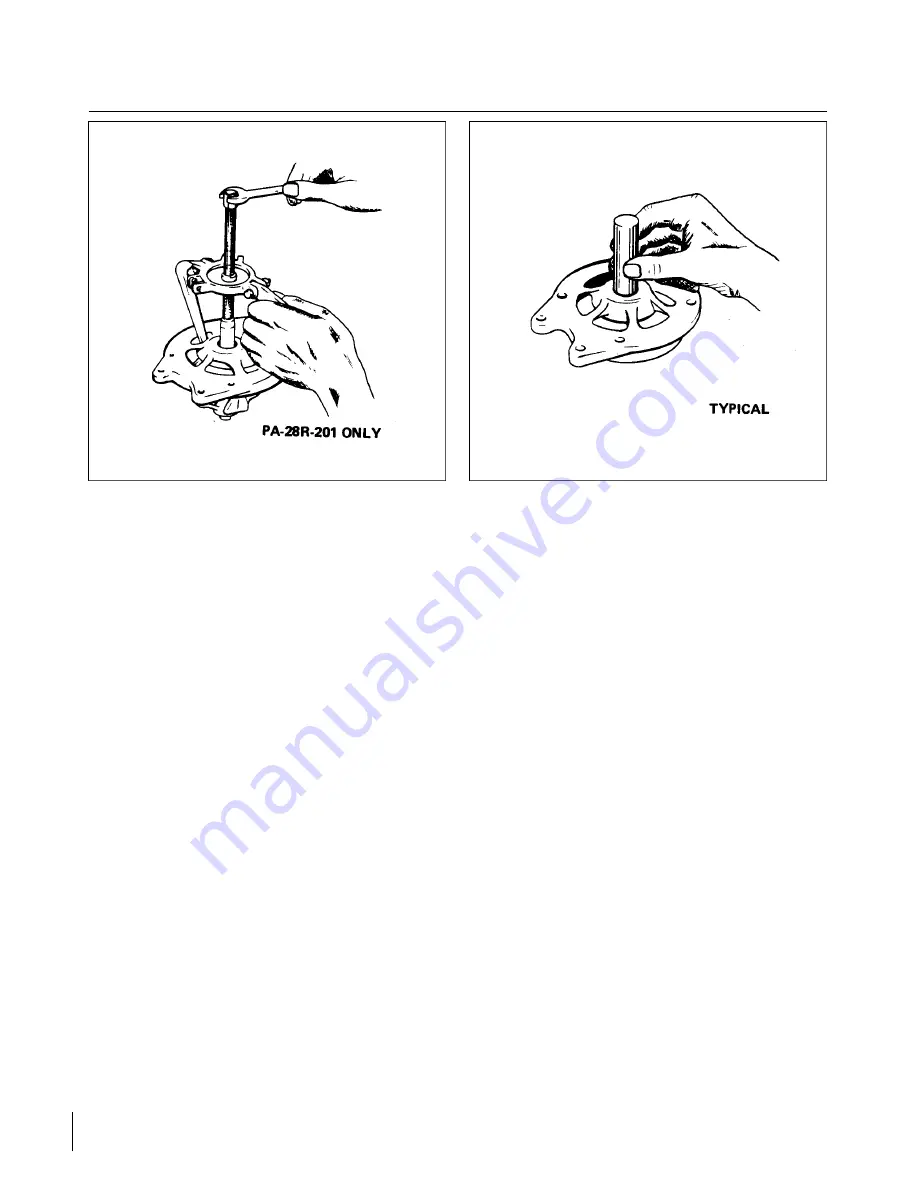

Figure 11-27. Removal of End Head Bearing

g. On PA-28R-201 models, to remove the drive end head from the rotor shaft, use a puller that grips on

the bearing retainer plate as shown in Figure 11-26. Do not attempt to remove by supporting the end

head and pressing on the shaft as this may result in distortion of the end head or stripping of the

retainer plate screws. Remove the three retainer plate screws and press the bearing out of the end head.

(Refer to Figure 11-27.) On PA-28R-201T models, support the drive end head and carefully press out

the rotor assembly. Remove the three retainer plate screws and press the bearing from the end head.

(Refer to Figure 11-27.)

11-38. INSPECTION AND TESTING OF COMPONENTS. Upon completion of the disassembly, all parts

should be cleaned and visually inspected for cracks, wear or distortion and any signs of overheating or

mechanical interference.

a.

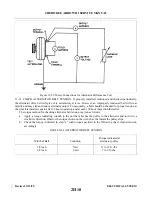

Rotor: The rotor should be tested for grounded or shorted windings. The ground test can be made with

test probes, connected in series with a 110-volt test lamp, an ohmmeter or any type of continuity tester.

(Refer to Figure 11-28.) There must not be any continuity between the slip rings and the rotor shaft or

poles. To test for shorted turns in the rotor windings, connect a voltmeter, ammeter and rheostat as

shown in Figure 11-29, or use an ohmmeter. Rotor current draw and resistance are listed in the

Alternator Service Test Specifications paragraph. Excessive current draw or a low ohmmeter reading

indicates shorted windings. No current draw or an infinite ohmmeter reading would indicate an open

winding.

b. Rectifiers: A diode rectifier tester will detect and pin point open or shorted rectifiers without going

through the operation of disconnecting the stator leads. However, if a tester is not available, test probes

and a No. 57 bulb, connected in series with a 12-volt battery, can be used in the following manner.

Touch one test probe to a rectifier heat sink and the other test probe to a lead from one of the rectifiers

in that heat sink. Then reverse the position of the leads. The test bulb should light in one direction and

not light in the other direction. If the test bulb lights in both directions, one or more of the rectifiers in

the heat sink is shorted. To pin point the defective rectifier, the stator leads must be disconnected and

the above test repeated on each rectifier. Open rectifiers can only be detected, when using the test bulb,

by disconnecting the stator leads. The test bulb will fail to light in either direction if the rectifier is

open.

Revised: 2/13/89

2H14

CHEROKEE ARROW III SERVICE MANUAL

ELECTRICAL SYSTEM

Summary of Contents for ARROW III

Page 4: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A4...

Page 12: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A12...

Page 94: ...Figure 4 2 Wing Installation Revised 2 13 89 1D22 CHEROKEE ARROW III SERVICE MANUAL STRUCTURES...

Page 171: ...lH3 INTENTIONALLY LEFT BLANK...

Page 172: ...lH4 INTENTIONALLY LEFT BLANK...

Page 286: ...THIS PAGE INTENTIONALLY LEFT BLANK Revised 2 13 89 2A8...

Page 528: ...INTENTIONALLY LEFT BLANK 2K10 THRU 2L24 2K10...