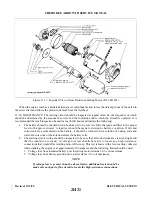

Figure 11-28. Testing Rotor for Ground

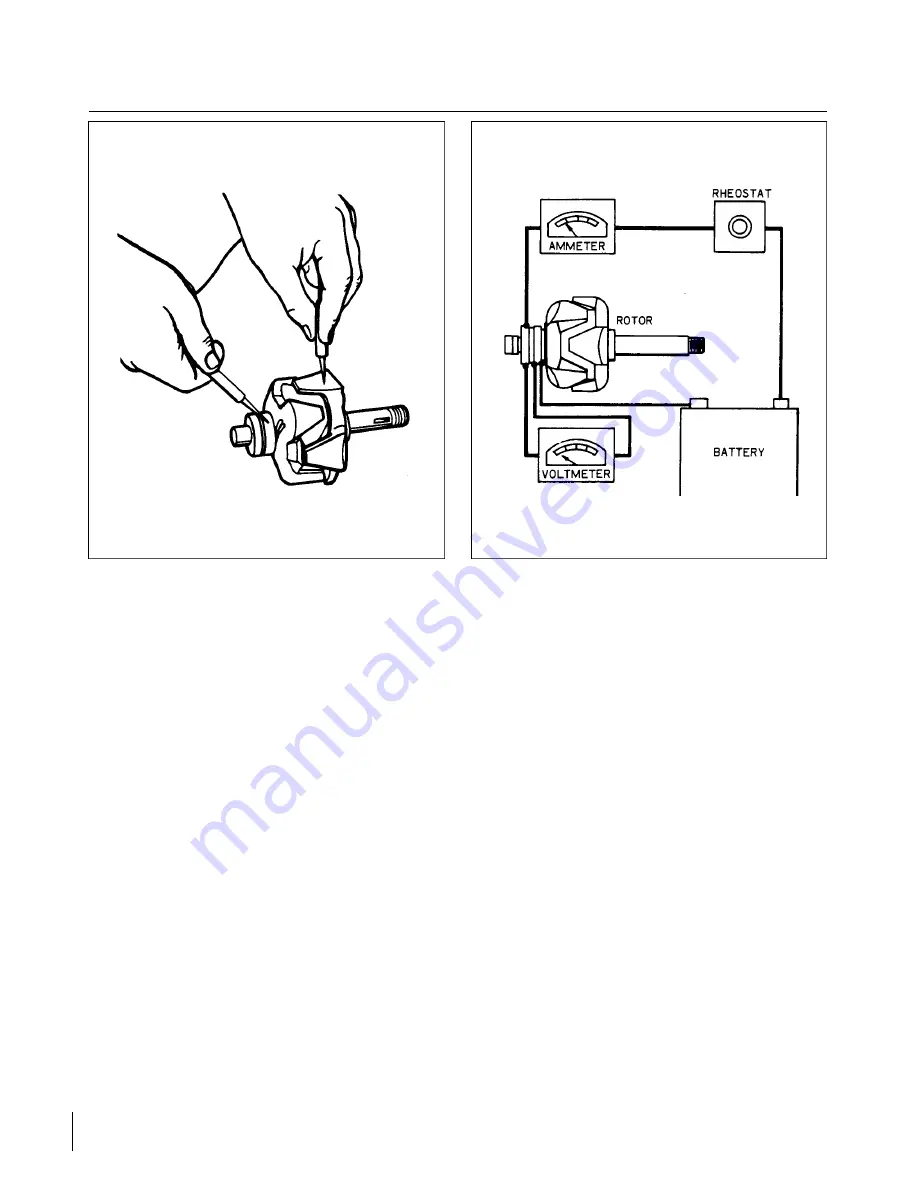

Figure 11-29. Testing Rotor for Shorts

c.

Stator: The stator can be tested for open or grounded windings with a 12-volt test bulb, described in

the rectifier section, or an ohmmeter, in the following manner. Separate the stator from the slip ring

end head just far enough to insert a fold of rags or blocks of wood. In other words, insulate the stator

from the end head. To test for grounded windings, touch one test bulb or ohmmeter probe to the

auxiliary terminal or any stator lead and the other test bulb or ohmmeter probe to the stator frame. If

the test bulb lights, or the ohmmeter indicates continuity, the stator is grounded. To test for open

windings, connect one test probe to the auxiliary terminal or the stator winding center connection and

touch each of the three stator leads. The test bulb must light or the ohmmeter must show continuity.

Due to the low resistance in the stator windings, shorted windings are almost impossible to locate.

H o w e v e r, shorted stator windings will usually cause the alternator to “growl” or be noisy during

operation and will usually show some signs of overheating. If all other electrical checks are normal

and alternator fails to supply its rated output, the stator should be replaced to determine whether or not

it is the faulty component.

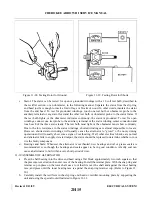

d. Bearings and Seals: Whenever the alternator is overhauled, new bearings and oil or grease seals are

recommended, even though the bearings and seals appear to be in good condition. A faulty seal can

cause an alternator to fail within a very short period of time.

11-39. ASSEMBLY OF ALTERNATOR.

a.

Press the ball bearing into the drive end head using a flat block approximately two inch square so that

the pressure is exerted on the outer race of the bearing. Install the retainer plate. With the snap ring and

retainer cup in place on the rotor shaft, use a tool that fits over the shaft and against the inner bearing

race, and press until the inner bearing race is against the snap ring retainer cup. (Refer to Figure 11-

30.)

b. Carefully install the rectifiers in the slip ring end head or rectifier mounting plate by supporting the

unit and using the special tools illustrated in Figure 11-31.

Revised: 2/13/89

2H15

CHEROKEE ARROW III SERVICE MANUAL

ELECTRICAL SYSTEM

Summary of Contents for ARROW III

Page 4: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A4...

Page 12: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A12...

Page 94: ...Figure 4 2 Wing Installation Revised 2 13 89 1D22 CHEROKEE ARROW III SERVICE MANUAL STRUCTURES...

Page 171: ...lH3 INTENTIONALLY LEFT BLANK...

Page 172: ...lH4 INTENTIONALLY LEFT BLANK...

Page 286: ...THIS PAGE INTENTIONALLY LEFT BLANK Revised 2 13 89 2A8...

Page 528: ...INTENTIONALLY LEFT BLANK 2K10 THRU 2L24 2K10...