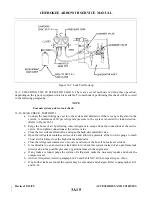

14-11. LEAK CHECK - METHOD II.

a.

Remove the access panel at the rear of the cabin to gain access to the service valves.

b. Remove the protective cap on the high pressure Schrader valve fitting and connect a charging hose

with a shutoff valve arrangement to the fitting. The charging hose must have a Schrader fitting or

adapter to fit the valve.

c.

Connect the other end of the charging hose to a small cylinder or refrigerant and purge the hose by

allowing a slight amount of refrigerant gas to escape from the Schrader valve fitting.

d. The cylinder of refrigerant should be placed upright in a container of warm (125°F max.) water on

a small scale.

e.

Allow approximately 1/2 pound of refrigerant to enter the system by opening the valve on the

charging hose and observing the weight change on the scale.

f.

Using an electronic leak detector, check all joints and repair any leaks.

g. After completion of repair of any leaks, proceed to check the system in accordance with one of the

methods outlined for any other leaks.

h. If no further repair is required on the system, it is now ready to evacuate in accordance with

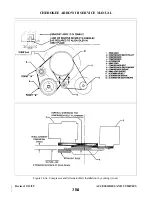

14-12. DISCHARGING. (Required only if system contains refrigerant.)

NOTE

Applies to Kent Moore J23500 or similar charging station. Refer to Figure

14-7.

a.

Close all valves on charging station.

b. Connect red high pressure charging line to high pressure Schrader valve at the evaporator fitting.

c.

Open valve 8 (high pressure control) on charging station one turn.

d. Hold end of blue low pressure charging line in a stop rag and slowly open valve 2 (low pressure

control) on charging station allowing refrigerant to exhaust from system into shop rag.

CAUTION

Refrigerant can cause freezing of skin. Be particularly careful not to allow

contact with the eyes.

Do not allow refrigerant to escape too rapidly, as excessive oil may be

carried out of system. When hissing stops, system is empty and valve should

be closed if no further work is planned.

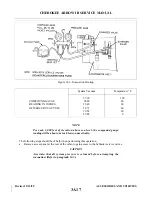

14-13. EVACUATING THE SYSTEM. If the system has been operated in a discharged condition or anytime

the system has been open to atmospheric pressure, the receiver-dehydrator must be replaced and the system

evacuated to remove any trapped air and moisture which has entered it. A vacuum pump capable of pulling 29

inches of mercury or better should be used. As we lower the pressure in the air conditioning system, we lower

the boiling temperature of the water (moisture) that may be present. Then we are able to pull this water, in the

form of vapor, out of the system. The following table demonstrates the effectiveness of moisture removal

under a given vacuum.

Revised: 2/13/89

3A16

CHEROKEE ARROW III SERVICE MANUAL

ACCESSORIES AND UTILITIES

Summary of Contents for ARROW III

Page 4: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A4...

Page 12: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A12...

Page 94: ...Figure 4 2 Wing Installation Revised 2 13 89 1D22 CHEROKEE ARROW III SERVICE MANUAL STRUCTURES...

Page 171: ...lH3 INTENTIONALLY LEFT BLANK...

Page 172: ...lH4 INTENTIONALLY LEFT BLANK...

Page 286: ...THIS PAGE INTENTIONALLY LEFT BLANK Revised 2 13 89 2A8...

Page 528: ...INTENTIONALLY LEFT BLANK 2K10 THRU 2L24 2K10...