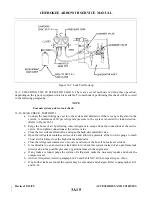

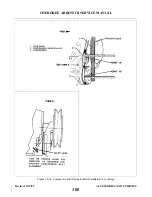

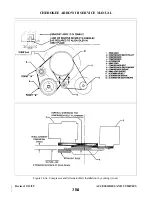

g. Alternator Belt Alignment: (Refer to Figure 14-9a.)

1. With the alternator belt installed, align the idler pulley in the belt plane by adding or removing

shims, P/N 62833-82 as required. Refer to paragraph 14-23 for belt tension adjustment.

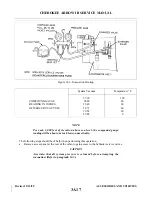

14-23. ADJUSTMENT OF DRIVE BELT TENSION.

a.

The adjustment of the York compressor and/or alternator drive belts installed on the PA-28R-201

is very important to obtain long belt life and proper component operation. (Refer to Parts Catalog

for belt numbers.) Adjust the belt tensions on PA-28R-201 as follows:

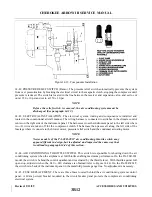

1. Tighten the new compressor belt to 120 lbs span tension and the new alternator belt to 90-100

lbs. span tension. When using the plastic type alternator belt, adjust the tension at 65-70 lbs for

new belt.

NOTE

The higher tension specified for a new belt is to compensate for the initial

stretch that takes place as soon as it is operated. These higher tension values

should not be applied to belts which previously have been used. See tensions

noted below for used belts.

2. Install the right front engine baffle and secure the side engine cowl latches, if previously

removed.

3. Run the engine for a 15 minute period at 1200 rpm.

WARNING

If the air conditioner is to be operated during ground servicing, the test area

should be clean and free of any loose objects lying on the ramp. Only the

service valve located on the evaporator assembly should be used for testing.

4. Shut down engine and recheck the belt tensions. If the compressor belt tension falls as low as

60 lbs., reset to 80 lbs. If the alternator belt tension falls as low as 50 lbs., retention to 70 lbs.

The plastic type belt should be between 35-40 lbs.

5. This tension check should be made at every 100 hours or annual inspection, whichever occurs

first.

6. Check all idler and bracket bolts for safety and replace engine cowling.

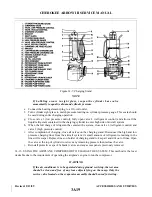

b. Adjust the Sankyo compressor on the PA-28R-201T as follows:

1. Rotate the compressor to obtain tension of 45 to 50 lbs. for new or old belts.

2. Run the engine for a 15 minute period at 1900 rpm with the compressor engaged.

WARNING

If the air conditioner is to be operated during ground servicing, the test area

should be clean and free of any loose objects lying on the ramp. Only the

service valve located on the evaporator assembly should be used for testing.

3. Shut down engine and recheck the belt tensions. New belt tension should fall back to desired

tension of 45 to 50 lbs. Old belts reinstalled should retain the 45 to 50 lbs. span tension.

4. This tension check should be made at every 100 hours or annual inspection, whichever occurs

first.

Revised: 2/13/89

3B5

CHEROKEE ARROW III SERVICE MANUAL

ACCESSORIES AND UTILITIES

Summary of Contents for ARROW III

Page 4: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A4...

Page 12: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A12...

Page 94: ...Figure 4 2 Wing Installation Revised 2 13 89 1D22 CHEROKEE ARROW III SERVICE MANUAL STRUCTURES...

Page 171: ...lH3 INTENTIONALLY LEFT BLANK...

Page 172: ...lH4 INTENTIONALLY LEFT BLANK...

Page 286: ...THIS PAGE INTENTIONALLY LEFT BLANK Revised 2 13 89 2A8...

Page 528: ...INTENTIONALLY LEFT BLANK 2K10 THRU 2L24 2K10...