CAUTION

When the six inch requirement cannot be complied with, one inch is

allowed as long as the electric cables and other lines are supported at least

every two inches; and, the oxygen tube(s) is protected by rubber neoprene

hose fastened in place with cable ties at the location the specific item crosses

or is near the oxygen tube(s). If an item is near the oxygen tube for a

certain distance, the oxygen tube for that distance must be covered.

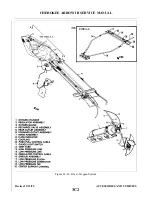

d. A minimum of 1/8 inch between tubing and structure adjoining the supported clamp, as shown in

e.

Where a tube passes through a grommet, the tube must not bear on the grommet in any way that

might cause cutting of the grommet in service as shown in Figure 14-18, Sketch D.

f.

While in service, items may receive vibrations causing them to come in contact with other parts of

the aircraft. With this in mind, low pressure tubing that is supported well enough to prevent

relative motion must have at least a minimum clearance of 1/8 inch from a projection (bolt, nut,

etc). Low pressure tubing that cannot be supported well enough to prevent motion must have a

minimum clearance of 1/8 inch allowed after the maximum travel of the tube. High pressure lines

are affected similarly but require 1/2 inch clearances. Refer to Figure 14-18, Sketch B.

10. Perform any other required maintenance as directed in AC 43.13-1A.

11. Clean components as necessary per the following subject-paragraph.

14-58. CLEANING AND PURGING OF OXYGEN SYSTEM COMPONENTS.

CAUTION

Care and critical attention must be exercised to prevent contamination of

oxygen system components by oil, grease, water, or foreign matter.

Compressed air used in cleaning or flushing tubes must be clean, dry,

filtered (oil free) air only.

NOTE

Solvents can be reused provided they do not become badly contaminated

with oil. This condition can be determined by thoroughly evaporating 100

milliliters of the liquid in a glass dish of a determined weight. Evaporation

may be accomplished by heating the dish at 200 degrees F° for one-half

h o u r. If after evaporation and cool down, the residue exceeded 100

milligrams in weight, the solvent cannot be used for this purpose.

Three methods are recommended for cleaning oxygen system components as follows:

1. Method I

a.

Vapor degrease affected part(s) with trichlorethylene.

b. Blow part(s) dry with a stream of compressed air or dry nitrogen.

Revised: 2/13/89

3C5

CHEROKEE ARROW III SERVICE MANUAL

ACCESSORIES AND UTILITIES

Summary of Contents for ARROW III

Page 4: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A4...

Page 12: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A12...

Page 94: ...Figure 4 2 Wing Installation Revised 2 13 89 1D22 CHEROKEE ARROW III SERVICE MANUAL STRUCTURES...

Page 171: ...lH3 INTENTIONALLY LEFT BLANK...

Page 172: ...lH4 INTENTIONALLY LEFT BLANK...

Page 286: ...THIS PAGE INTENTIONALLY LEFT BLANK Revised 2 13 89 2A8...

Page 528: ...INTENTIONALLY LEFT BLANK 2K10 THRU 2L24 2K10...