TABLE III-I. INSPECTION REPORT (cont)

18.

Refer to latest revision of Piper Service Bulletin 578.

19.

Inspect brushes every 100 hours if used for training or every 500 hours if used for normal service. (Refer

to latest vendor service publications.)

20.

Refer to flight manual supplement for preflight and flight check, for intended function in all modes.

21.

Refer to latest revision of Bendix Service Bulletin 612 for inspection of magneto and ignition

harnesses.

22.

Refer to latest revision Teledyne Continental Service Bulletin M86-11.

23.

Examine cables for broken strands by wiping the cable along the length of the cable. Visually check for

damage. Replace all damaged cables. Refer to latest revision of Advisory Circular 43.13.

24.

Piper Service Bulletin 884 compliance requires lock wiring of V-band couplings.

25.

Latest models, S/N’s 2837001 (PA-28R-201) and S/N’s 2803001 (PA-28R-201T) are equipped with

auxiliary electric backup vacuum systems that require replacement after 500 hours of operation time.

26.

Piper Service Bulletin 896 compliance requires installation and usage of shoulder harnesses.

27.

Refer to latest revision of Piper Service Bulletin 866a. Aircraft S/N’s 2837001 (PA-28R-201) and up,

and S/N’s 2803001 (PA-28R-201T) and up, have no backup extender system in the landing gear system

installed as standard equipment.

28.

When servicing or inspecting vendor equipment installed in Piper aircraft, it is the user’s responsibility to

refer to the applicable vendor service publications.

29.

Ensure after cleaning engine that all rod end bearings are lubricated with at least 3 drops of 100W motor

oil.

30.

All inspections or operations are required at each of the inspection intervals as indicated by an (O). Both

the annual and 100 hour inspection are complete inspections of the airplane, identical in scope, while

both 500 and 1000 hour inspections are extensions of the annual or 100 hour inspections, which require a

more detailed examination of the airplane and overhaul or replacement of some major components.

Inspections must be accomplished by persons authorized by the FAA.

31.

Refer to latest revision of Service Bulletin 856.

32.

Inspect Teflon bushing (lower to upper cowling attachment) for condition at each 100 hours. Replace

bushing on condition, but no later than 500 hours time in service. Inspect pin for condition and replace as

necessary.

33.

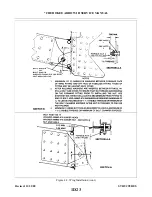

If not already installed, add access panels per instructions in Section IV, Paragraph 4-55a. See latest

revision of Piper Service Bulletin 977.

34.

Special care should be taken to inspect stabilator control cables beneath aft baggage compartment floor.

Add access panels per instructions in Section IV, Paragraph 4-55a, to ease this inspection.

Interim Revision: 2/21/95

1D16

CHEROKEE ARROW III SERVICE MANUAL

INSPECTION

Summary of Contents for ARROW III

Page 4: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A4...

Page 12: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A12...

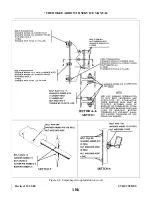

Page 94: ...Figure 4 2 Wing Installation Revised 2 13 89 1D22 CHEROKEE ARROW III SERVICE MANUAL STRUCTURES...

Page 171: ...lH3 INTENTIONALLY LEFT BLANK...

Page 172: ...lH4 INTENTIONALLY LEFT BLANK...

Page 286: ...THIS PAGE INTENTIONALLY LEFT BLANK Revised 2 13 89 2A8...

Page 528: ...INTENTIONALLY LEFT BLANK 2K10 THRU 2L24 2K10...